Schwerlastplatten: Das ultimative Bodensystem für Industrie und Gewerbe

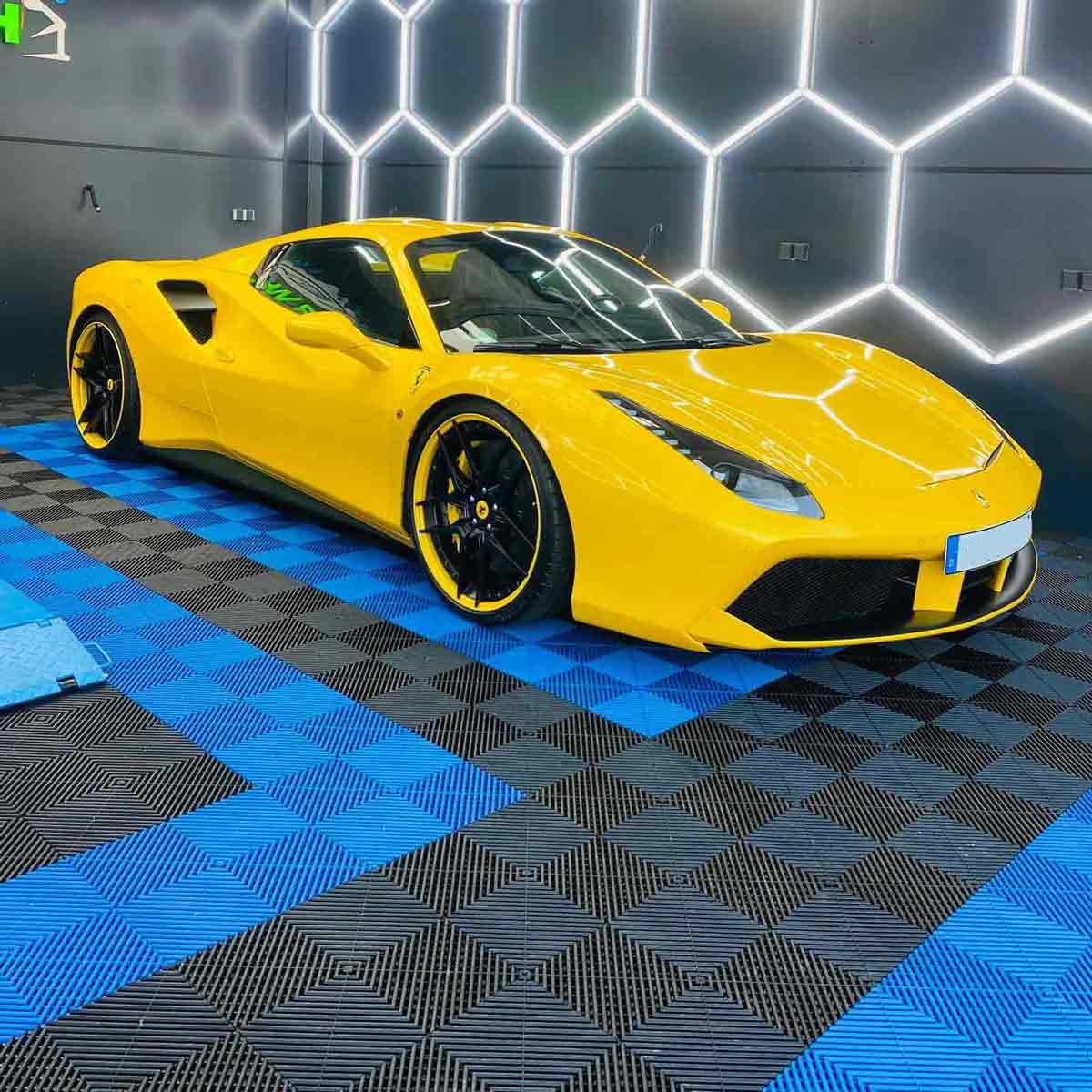

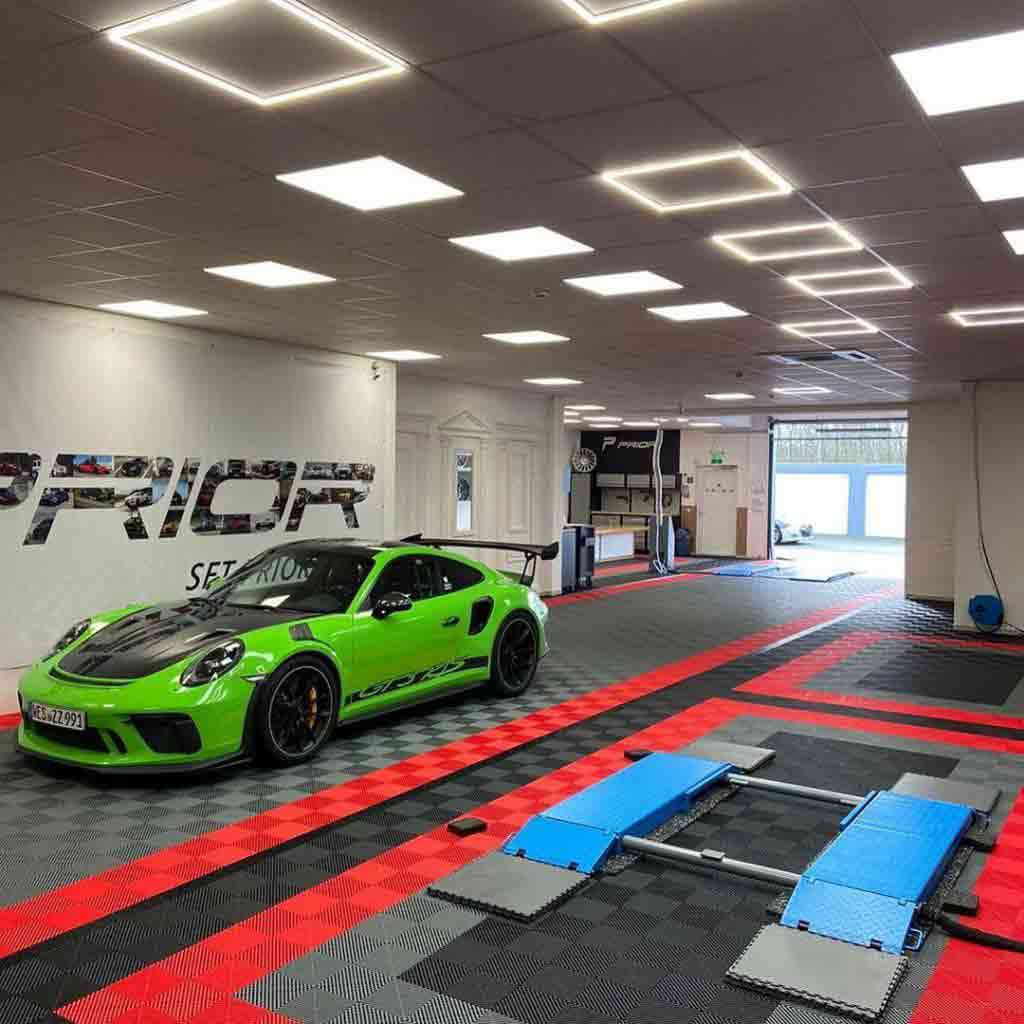

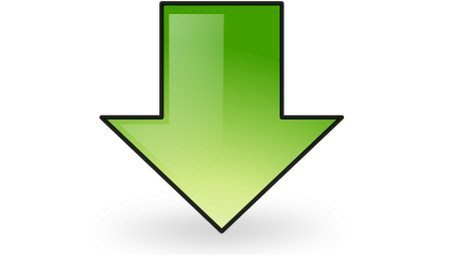

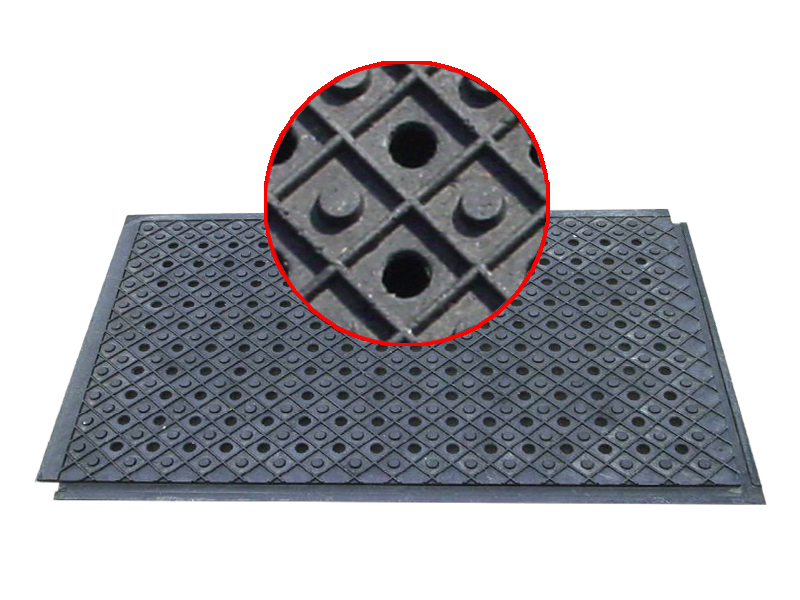

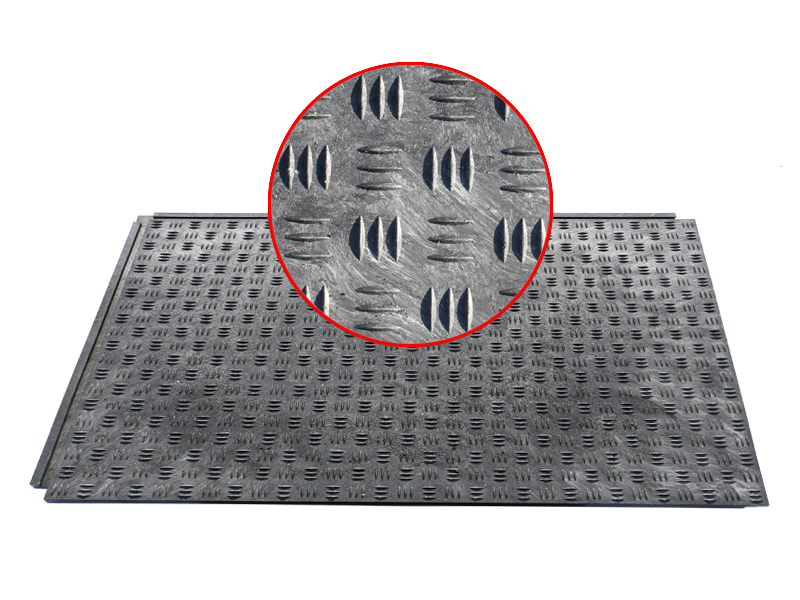

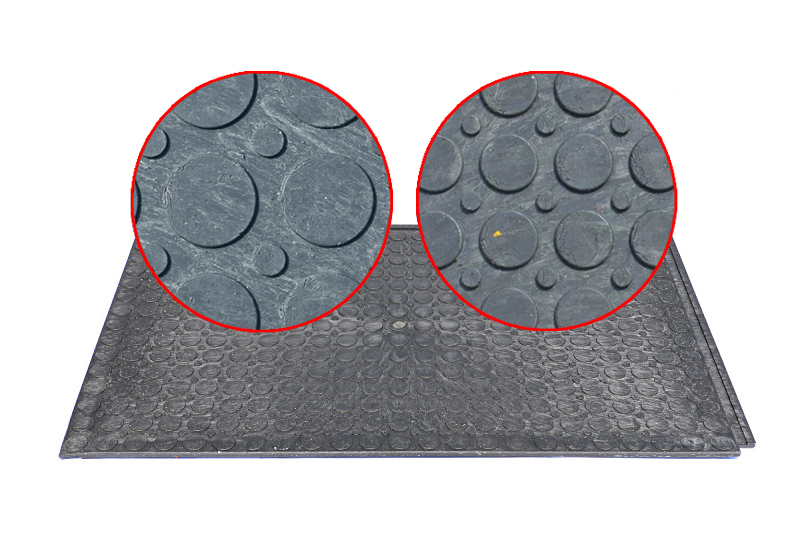

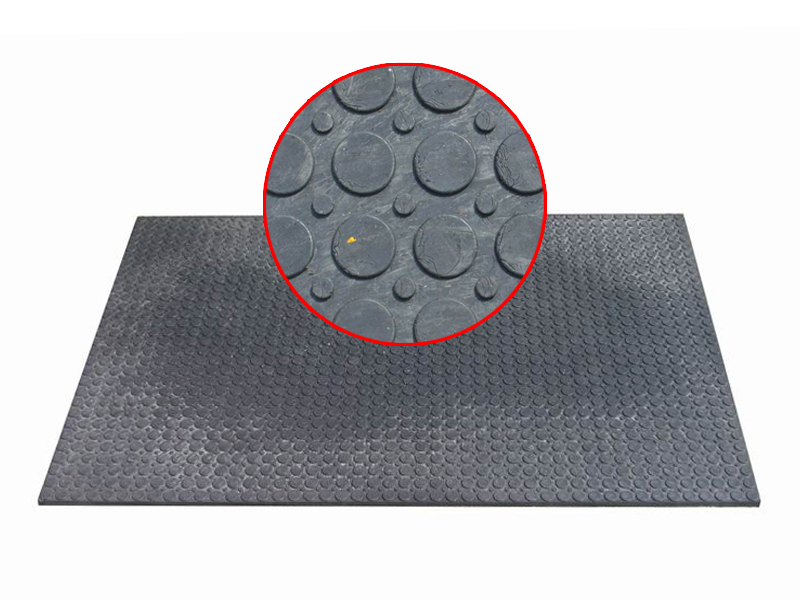

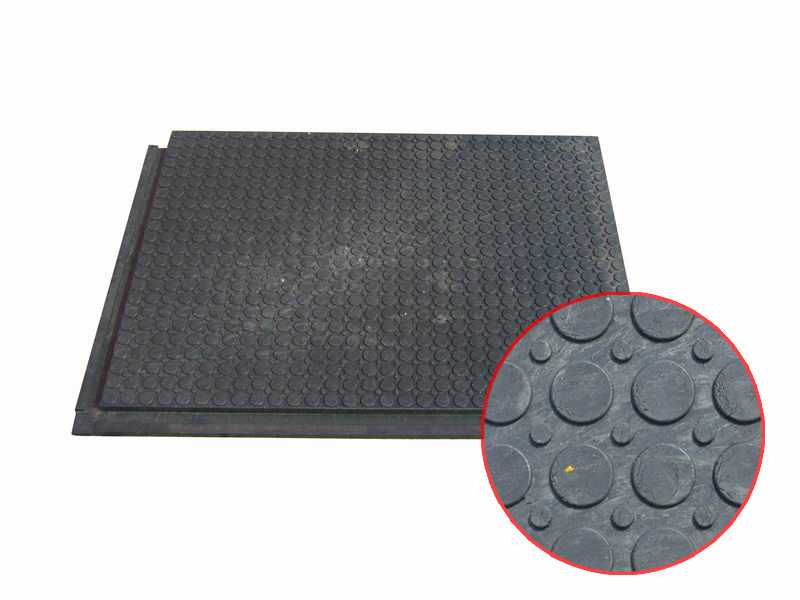

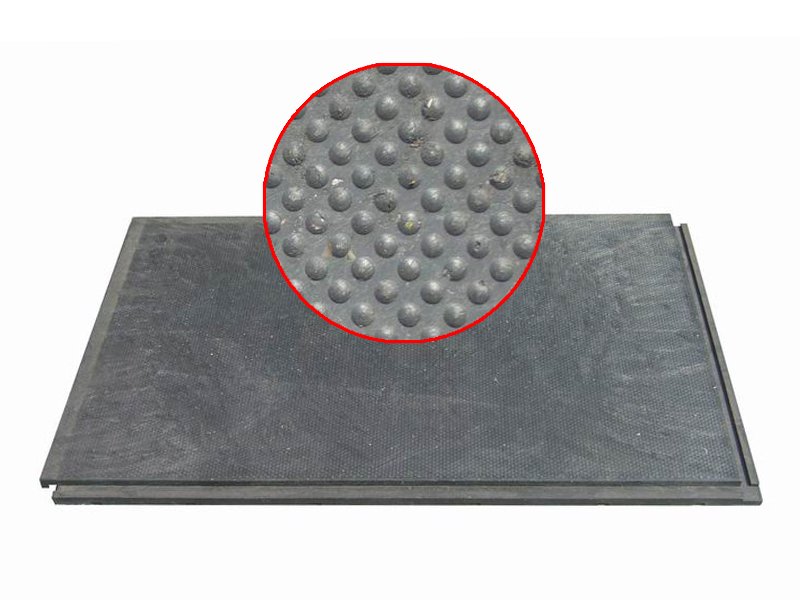

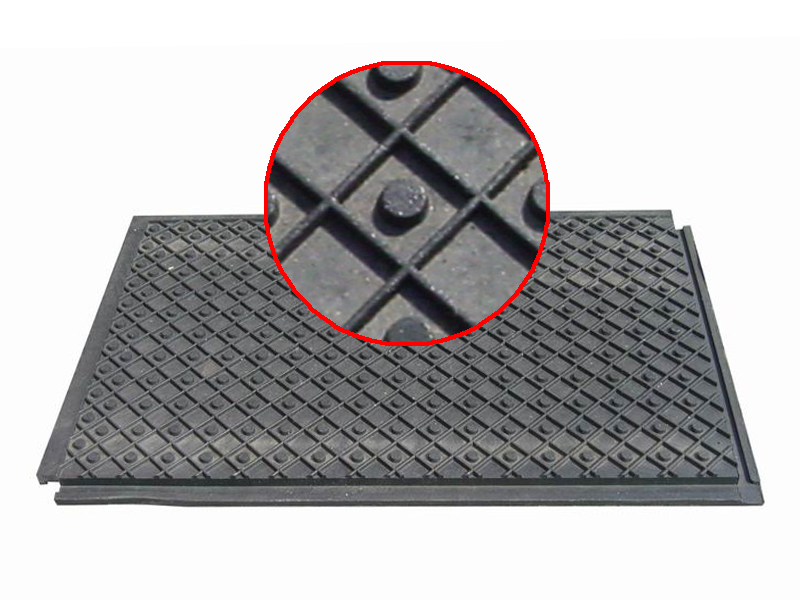

Wenn Sie auf der Suche nach einer robusten und langlebigen Bodenlösung für Ihr Unternehmen sind, dann sind Sie bei uns genau richtig. Unsere Schwerlastplatten sind nicht nur extrem belastbar, sondern auch vielseitig einsetzbar. Hergestellt aus hochwertigem PVC-Recyclingmaterial, bieten diese Platten eine hervorragende thermische Isolierung, hohe Rutschfestigkeit und chemische Beständigkeit.

Warum Schwerlastplatten aus Kunststoff wählen?

Im Gegensatz zu herkömmlichen Metallplatten sind unsere Schwerlastplatten aus Kunststoff leichter, einfacher zu warten und bieten dennoch eine hohe Tragfähigkeit. Sie sind UV-stabil, wetterfest und können sowohl drinnen als auch draußen verwendet werden.

Vorteile der Schwerlastplatte:

- Schnelle Montage und Demontage

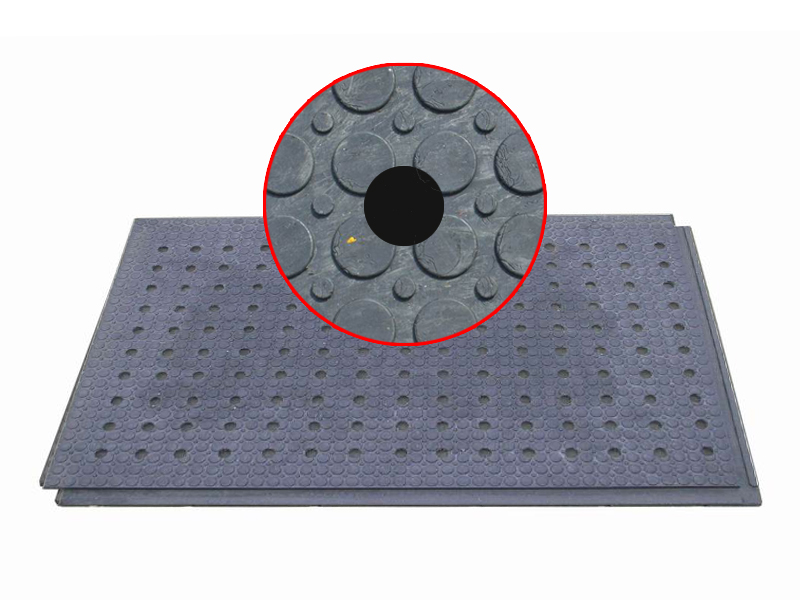

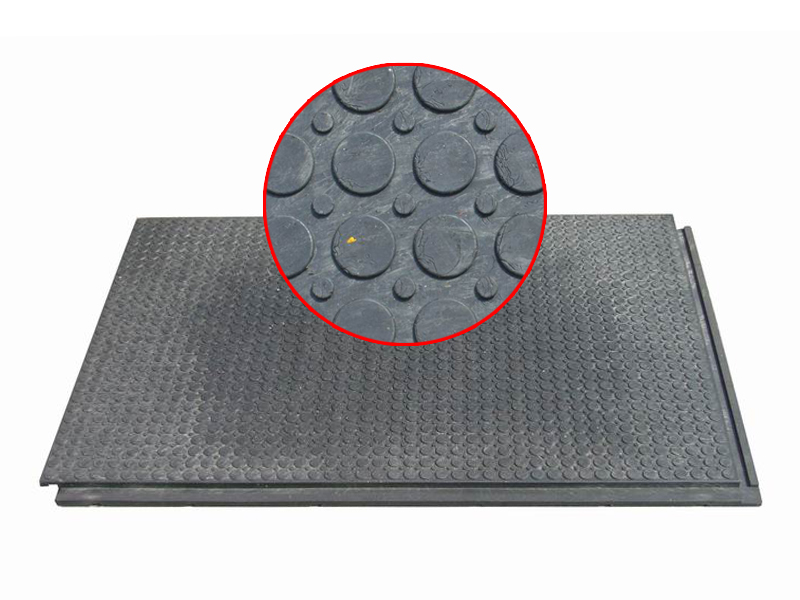

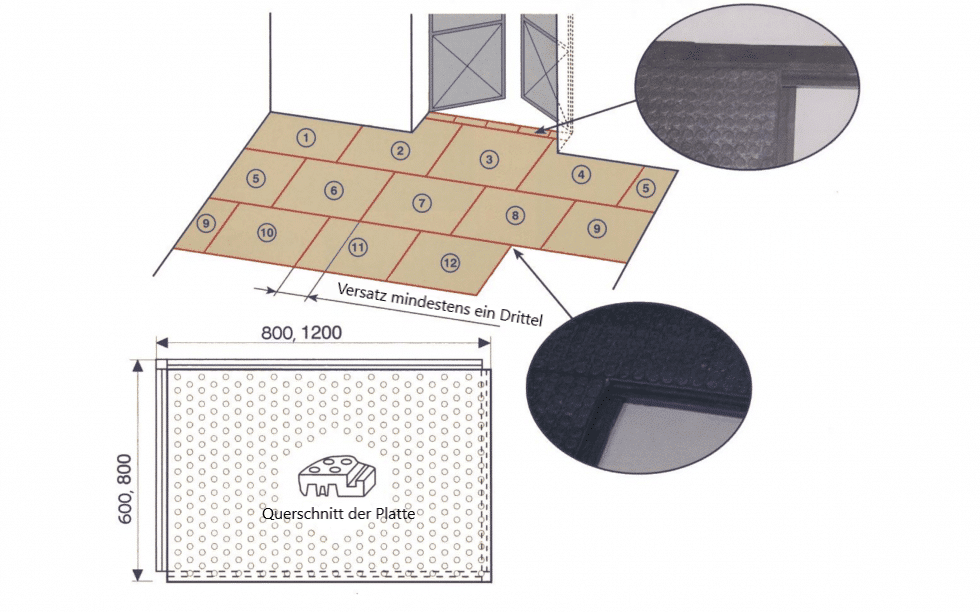

- Umgebendes Nut- und Federsystem für sicheren Halt

- Optimaler Grip auf weichen und unbefestigten Flächen

- Umweltfreundlich durch Verwendung von PVC-Recyclingmaterial

Jetzt Schwerlastplatten kaufen und von unseren Angeboten profitieren!

In unserem Online-Shop finden Sie eine breite Palette von Schwerlastplatten zu günstigen Preisen. Egal, ob Sie sie für Industriehallen, Lagerbereiche oder Ausstellungsflächen benötigen, wir haben das richtige Produkt für Sie.

Schwerlastplatten aus Kunststoff: Eine Investition, die sich lohnt

Investieren Sie in unsere Schwerlastplatten aus Kunststoff und profitieren Sie von einer langlebigen, pflegeleichten und kosteneffizienten Bodenlösung. Unsere Platten sind nicht nur preiswert, sondern auch von höchster Qualität.

Egal, ob Sie ein großes Industrieunternehmen oder ein kleines Gewerbe betreiben, unsere Schwerlastplatten sind die ideale Wahl für Sie. Mit ihrer hohen Belastbarkeit, Langlebigkeit und Vielseitigkeit sind sie die perfekte Lösung für jeden Bedarf. Besuchen Sie unseren Online-Shop und entdecken Sie unser umfangreiches Angebot.

Areas of application:

- Industry, warehouses, workshops and production hall

- Horse and cattle stables

- stages

- concert events

- Dog boxes, fitness

- makeshift ways

- sporting and cultural events

- Circus event, folk festivals, zoos

- Parking spaces, driveways in garages

- Events, construction sites

- mobile construction roads

- mobile access roads

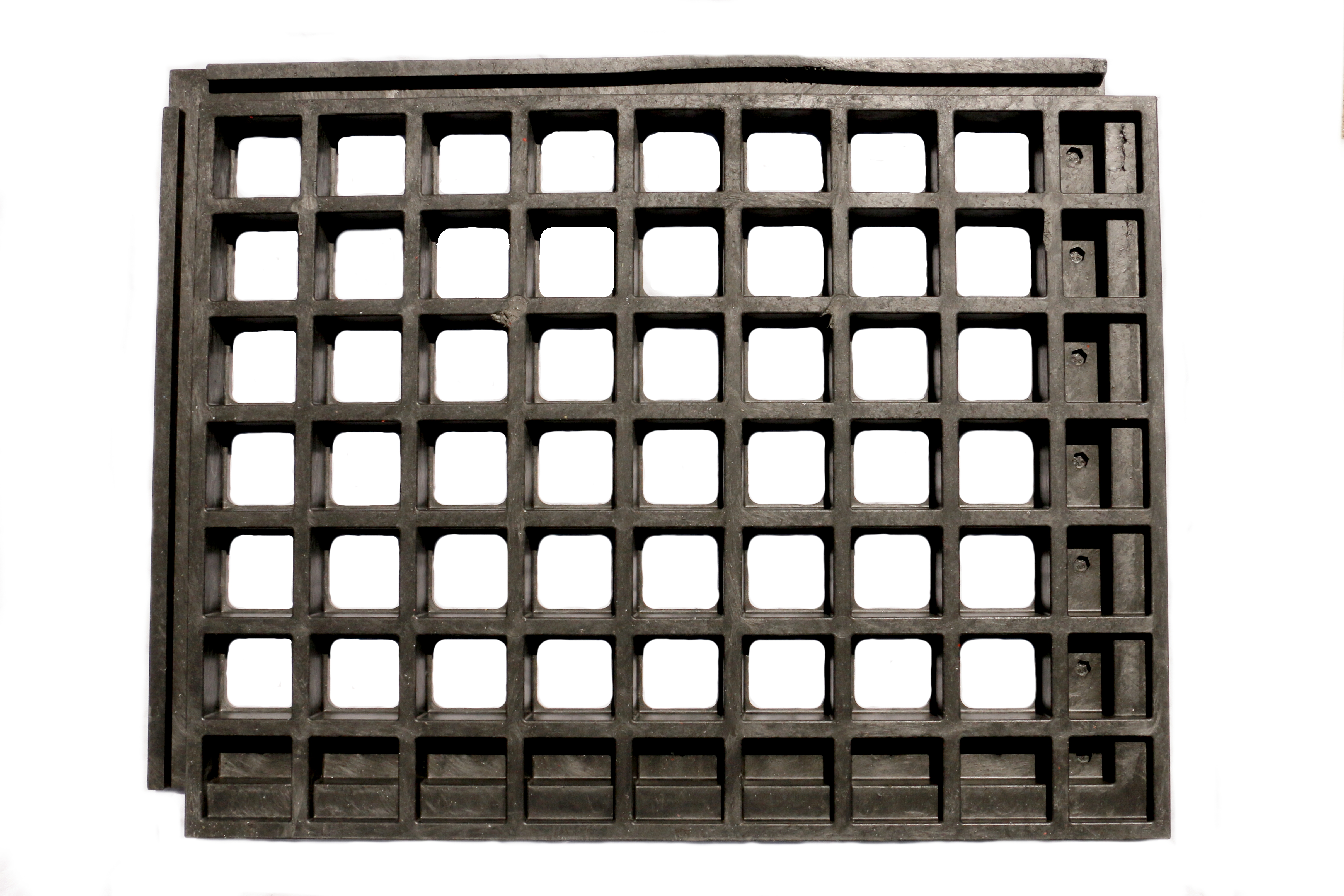

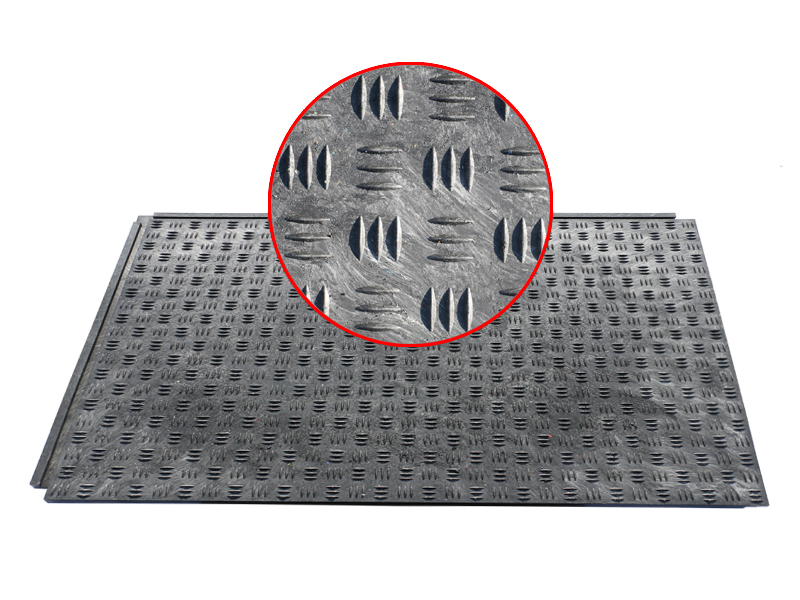

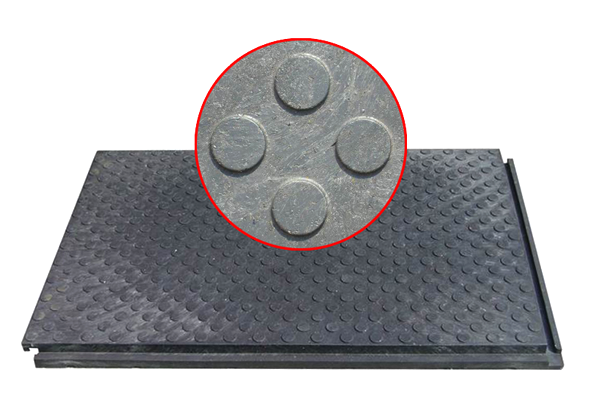

The panels are connected by a circumferential fold and groove system.

Advantages of the heavy-duty plates:

- Chemical resistance

- Flame retardant (B1)

- Easy maintenance

- Fast assembly and disassembly

- Compact to store and transport

- High resilience

- Excellent thermal insulation

- inhibits impact noise

- Can be used indoors and outdoors and can therefore be reused

- Lighter weight than metal plates, do not rust and do not conduct electricity

- For brisk heavy traffic by trucks, forklifts, ants or machines

The advantages of heavy-duty panels in the construction industry

Heavy-duty panels are an important component in the construction industry because they are strong, durable, and highly resilient. They are perfect for use in industrial applications as they can withstand high loads without suffering any damage. Some of the benefits of heavy duty panels in the construction industry include:

High load capacity: heavy duty panels can withstand very high loads, such as from heavy machinery and equipment. This increases safety on construction sites and reduces the risk of accidents.

Durability: Heavy-duty slabs are extremely durable and require little maintenance. This reduces the total cost of ownership and increases the life of the flooring.

Ease of installation: heavy-duty tiles are easy to install and can be laid on almost any surface. They require no special preparation or treatment of the substrate.

Weather resistant: heavy-duty tiles are resistant to weather conditions and are therefore suitable for outdoor use.

Environmentally friendly: heavy-duty slabs are often made from recycled materials and can be reused at the end of their life.

Overall, heavy-duty panels are an ideal solution for the construction industry because they offer high load-bearing capacity, durability, ease of installation, weather resistance and environmental friendliness.

Maximum load-bearing capacity: how heavy-duty panels increase safety

Heavy-duty panels are known for their high load-bearing capacity and ability to withstand very high loads, making them an ideal choice for industrial applications. Using heavy-duty slabs can increase safety on construction sites by reducing the risk of accidents caused by destroyed flooring.

Slip resistance: heavy-duty slabs have a slip-resistant surface that meets safety standards and provides a high level of traction, which is important for preventing slip-and-fall accidents.

Low maintenance: heavy-duty slabs require little maintenance and are durable, which reduces overall operating costs.

Overall, heavy-duty slabs increase safety on construction sites due to their high load-bearing capacity, slip resistance, weather resistance, ease of installation and low maintenance. They are the best choice for environments where safety and durability are critical.

Heavy-duty panels: the durable choice for outdoor use.

Heavy-duty slabs are an excellent choice for outdoor use because they are durable, robust and resistant to weathering. They are perfect for use in industrial applications such as warehouses, parking lots, factory floors and construction sites. Some of the benefits of heavy duty slabs for outdoor use include:

Environmentally friendly: heavy-duty slabs are often made from recycled materials and can be reused at the end of their life.

Overall, heavy duty slabs are a fantastic choice for outdoor use because they are durable, sturdy, weather resistant, slip resistant, and environmentally friendly. They offer a high level of safety and durability required for outdoor use

FAQ Schwerlastplatten

Heavy-duty panels are suitable for a variety of applications, especially in areas where there is a high weight or heavy loads. Some of the common uses include:

Warehouses and factory floors: Heavy-duty slabs are great for use in warehouses and factory floors because they are sturdy enough to support the weight of racks, machinery and trucks.

Parking lots: Slabs are also excellent for use as parking lot surfacing.

Driveways: Also a good choice for use as driveways.

Workshops: Best suited for use in workshops.

Outdoor applications: Heavy duty slabs are also suitable for outdoor applications such as walkways, driveways or parking lots. They are frost and UV resistant and can therefore be used well in harsh environments.

Indoor applications: such as flooring in warehouses, workshops or garages. They are easy to clean and maintain and provide a safe and non-slip surface.

Overall, heavy duty tiles are suitable for a wide range of applications where there is a high weight or heavy loads. They are robust, durable and easy to clean and are suitable for both indoor and outdoor use.

Heavy duty PVC flooring has many advantages, including:

Durability: PVC is a tough and durable material that is resistant to wear, scratches and damage. It is therefore particularly suitable for use in high traffic areas such as warehouses, factory floors or parking lots.

Slip resistance: PVC flooring has a non-slip surface, which is beneficial in terms of safety. It is especially useful in areas where there is a high risk of slips or falls, such as workshops or warehouses.

Easy maintenance: PVC floors are easy to clean and maintain. They do not require any special cleaning products or maintenance and can be cleaned with simple products such as soap and water.

Weather resistance: PVC floors are resistant to moisture, mold and rot, which makes them particularly suitable for outdoor use.

Cost-Effectiveness: PVC floors tend to be more cost-efficient than other flooring materials, especially in the long run. They are less expensive to purchase and require less maintenance and repairs.

Soundproofing: PVC floors also have good soundproofing, which can be beneficial in areas where noise reduction is desired.

Overall, PVC heavy-duty flooring provides a durable, slip-resistant, easy-to-maintain, and weather-resistant surface that can be used indoors or outdoors. There are also many design variations and it is more cost effective than other flooring materials.

Heavy-duty panels can indeed be laid over a lawn. However, there are some important factors to consider ensuring that the panels are installed properly and sturdily.

It is important that the ground on which the panels are laid is firm enough to support the weight of the panels and the people and vehicles walking on them. If the ground is not firm enough, there may be unevenness.

It is important that the slabs are laid horizontally and parallel to each other to create a stable and secure surface.

It is also important that the slabs are securely and firmly joined together to create a stable and safe surface.

If the slabs will be used as a parking lot or driveway, make sure they have a proper slope to allow water to drain away.

Overall, heavy-duty slabs can be installed over a lawn, but it is important that the surface is properly prepared and that the slabs are installed securely and sturdily to create a safe and durable surface.

Ein Schwerlastboden ist dafür konzipiert, extremen Belastungen standzuhalten. Dies umfasst das Gewicht von schweren Maschinen, Fahrzeugen und Geräten. Er ist in der Lage, hohe Punktlasten aufzunehmen, wie sie beispielsweise von den Stützbeinen eines Krans oder den Rädern von Baufahrzeugen ausgeübt werden. Weiterhin ist er beständig gegenüber dynamischen Lasten, die etwa durch das Befahren mit schweren Gabelstaplern oder das Verschieben von schweren Gegenständen entstehen. Neben der mechanischen Belastbarkeit weist der Schwerlastboden auch eine hohe Widerstandsfähigkeit gegenüber chemischen Substanzen auf, sodass er auch in chemisch aggressiven Umgebungen wie in einigen industriellen oder handwerklichen Betrieben eingesetzt werden kann. Seine Konstruktion ist zudem auf Langlebigkeit ausgelegt, was bedeutet, dass er auch dauerhaften Belastungen über längere Zeiträume ohne signifikante Abnutzung oder Schaden widerstehen kann.

Die Lebensdauer eines Schwerlastbodens kann je nach Material, Qualität, Beanspruchung und Wartung variieren. Ein Schwerlastboden aus hochwertigen Materialien, der sachgemäß installiert und gepflegt wird, kann unter normalen Einsatzbedingungen mehrere Jahre bis Jahrzehnte halten. Regelmäßige Wartung und die Vermeidung von extremen Bedingungen, die über die Spezifikationen des Bodens hinausgehen, tragen wesentlich zur Verlängerung der Lebensdauer bei. Außerdem kann die Lebensdauer durch die Art und Frequenz der Belastung, wie ständige Schwerlastverkehr, chemische Einflüsse oder extreme Temperaturen beeinflusst werden. Hersteller bieten oft eine Garantie, die einen Anhaltspunkt für die Mindestlebensdauer geben kann. Es ist wichtig, die spezifischen Empfehlungen des Herstellers zu berücksichtigen und den Boden entsprechend zu nutzen, um seine maximale Lebensdauer zu erreichen.