INHALTSVERZEICHNISS

PVC Industrial Flooring: The ultimate guide for your business

In modern industry, flooring is a critical factor in safety, efficiency and aesthetics. PVC industrial flooring has established itself as one of the best options for industrial businesses. In this article, we will take an in-depth look at the topic and find out why PVC industrial flooring is the right choice for your business.

What is a PVC industrial floor?

A PVC industrial floor is a flooring specifically designed for use in industrial environments. It is made of polyvinyl chloride, a plastic material known for its durability and resistance.

What is the best industrial flooring?

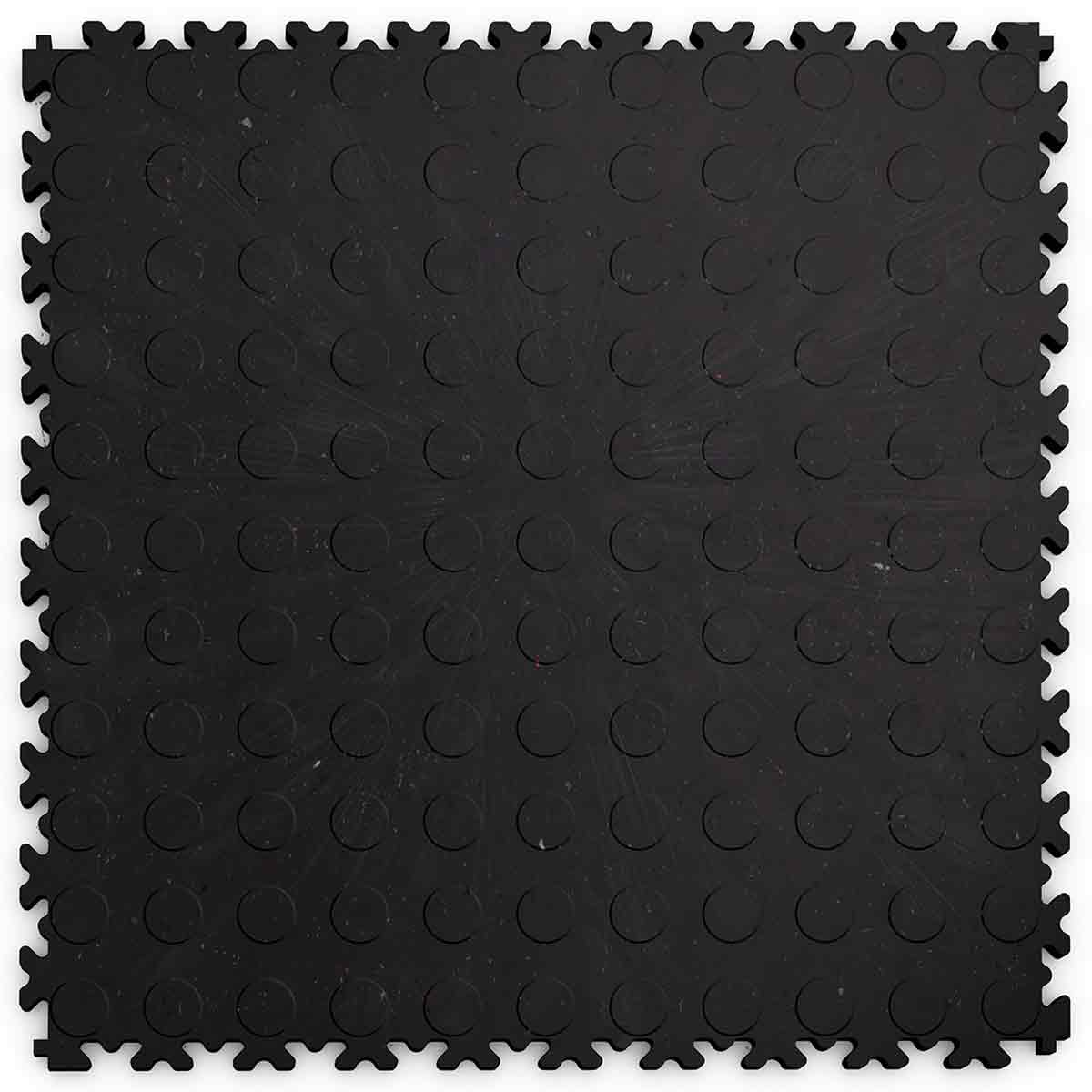

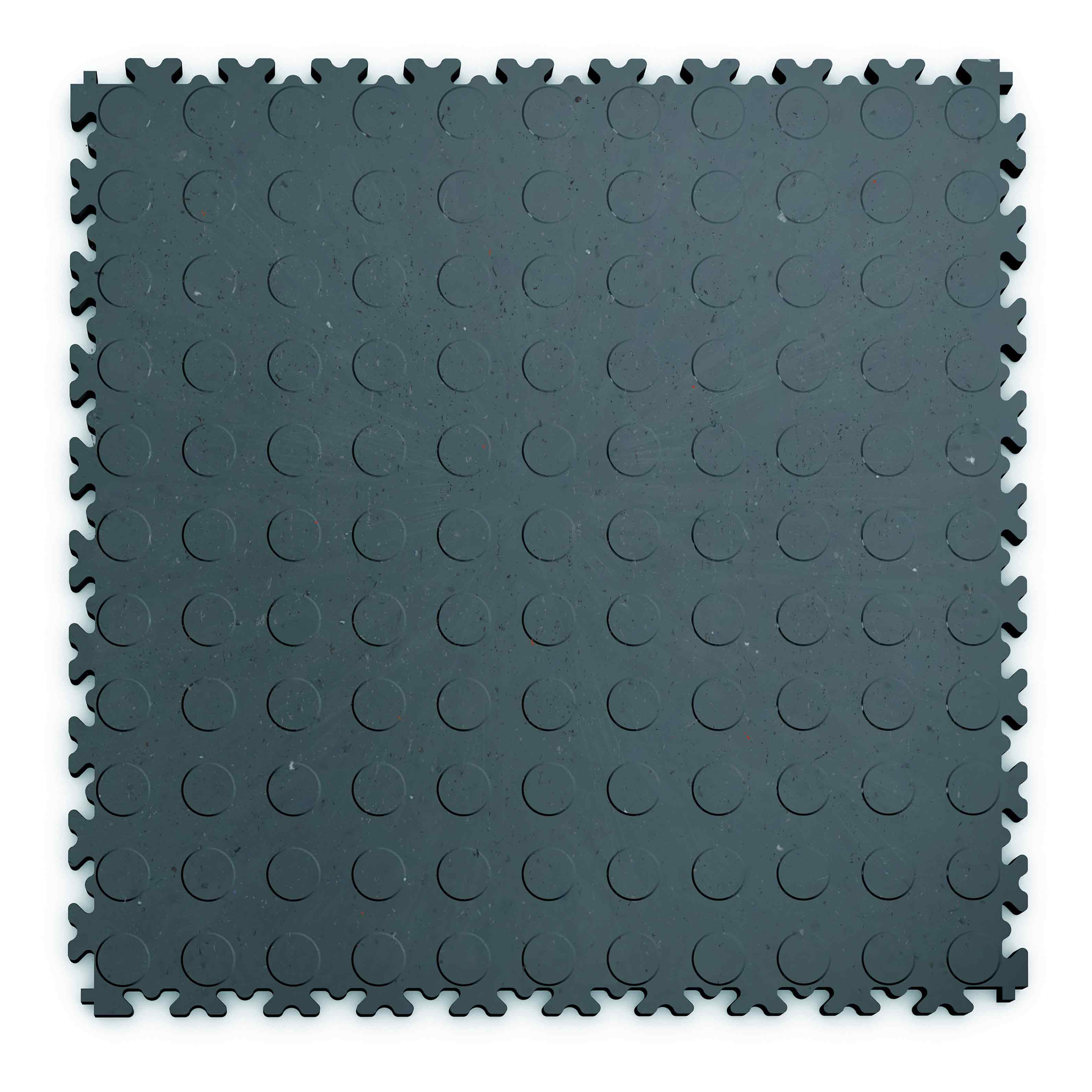

Industrial tiles made of PVC are durable, easy to clean and environmentally friendly. Thanks to click system, they are easy to install, visually appealing and immediately loadable. An ideal choice for industrial flooring.

Advantages of PVC industrial flooring

Where is industrial flooring used?

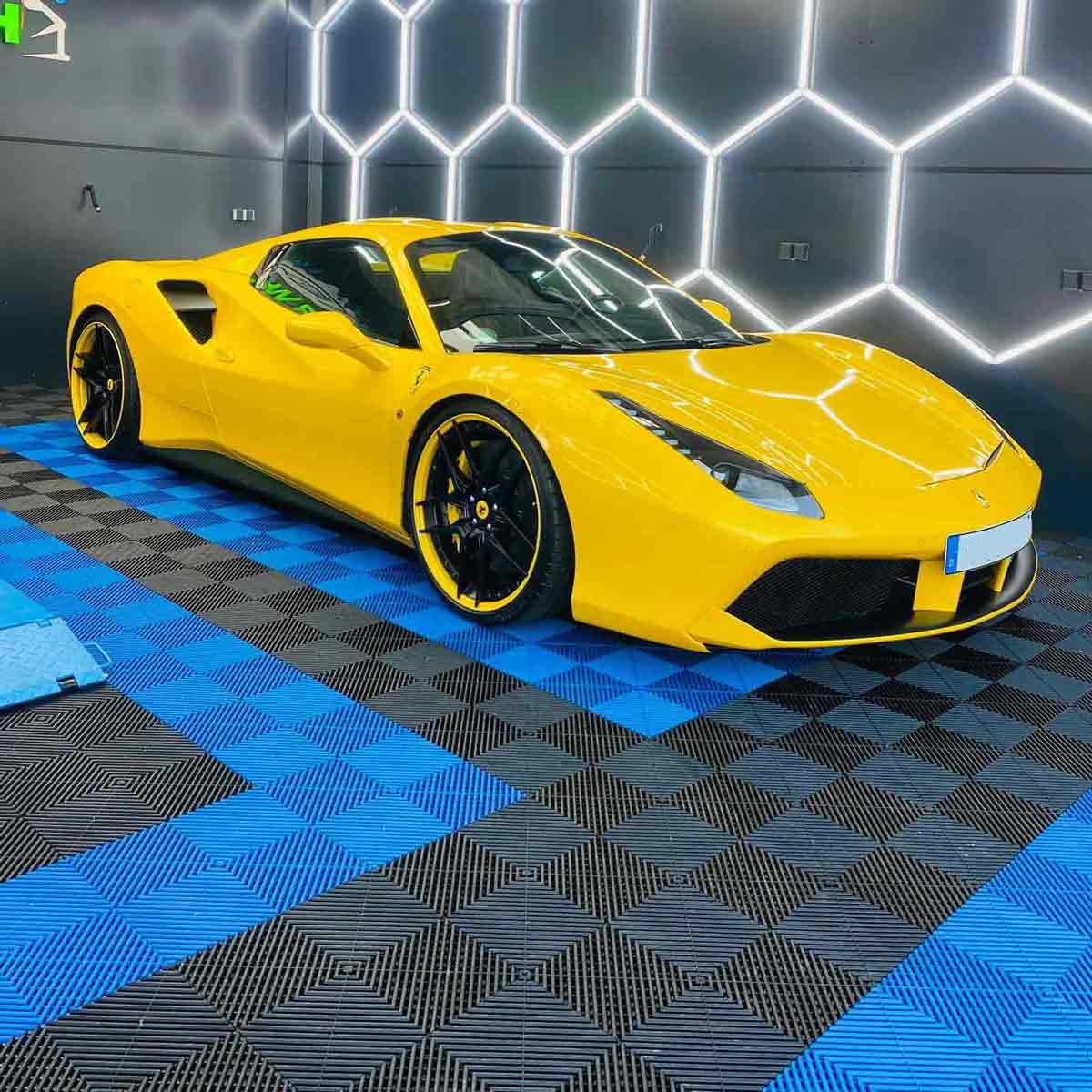

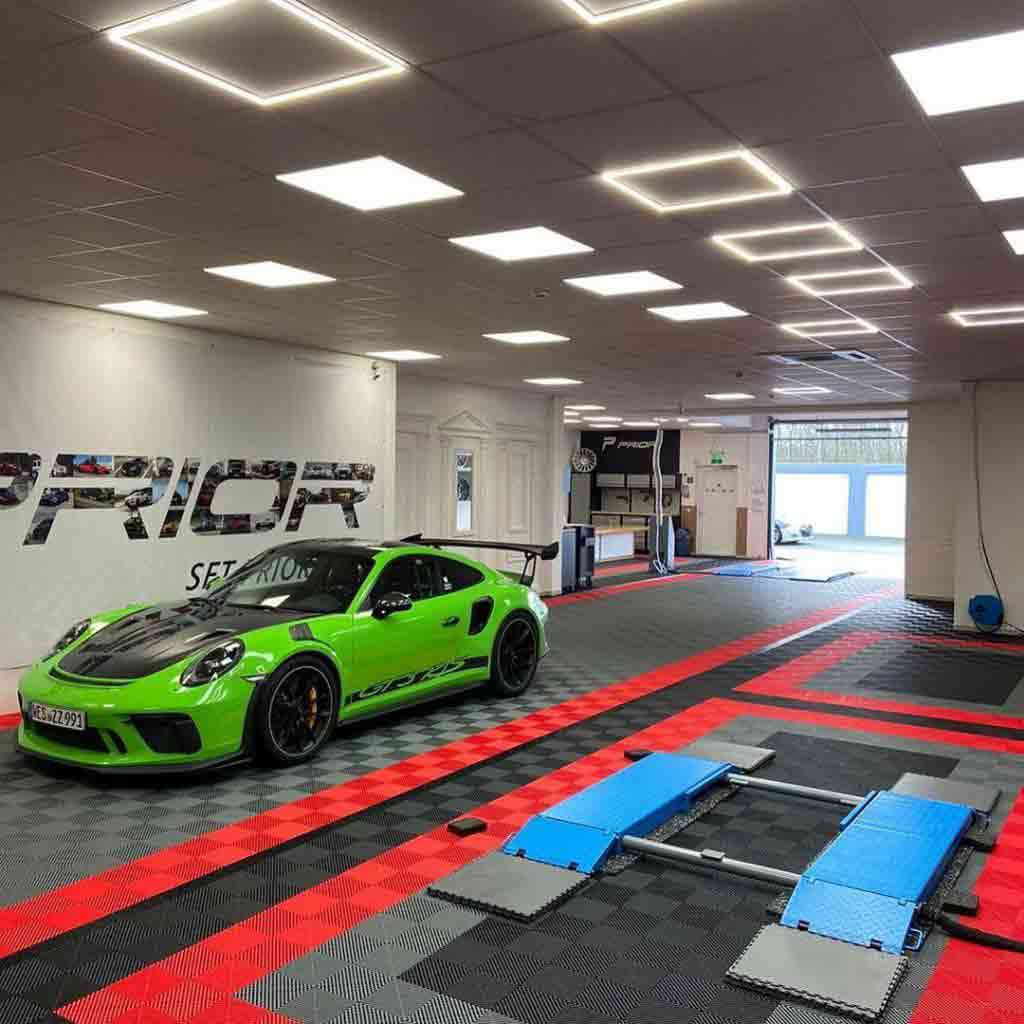

Workshops, garages, all kinds of manufacturing halls, warehouses, mechanical engineering, automotive and vehicle industry, car dealerships, large-scale industry ...

It does not always have to be used in industrial plants, also in public buildings, hotels, banks, wholesale retail, exhibition halls, sports studios, vintage car garages ... much is demanded of the floor

The challenge

The challenge with floor remediation is to find a solution that can be implemented quickly and with minimal disruption to ongoing operations. Time is money, and any downtime can mean financial losses.

The problem of downtime

Any type of refurbishment work carries the risk of downtime, which has a direct impact on productivity and turnover. A complete floor renovation usually means that the hall in question cannot be used for the duration of the work. This is a major problem, because downtime means that no production takes place, no orders are processed and ultimately no money is earned.

Clearing and storage

Another problem is clearing the hall. Where do you put all the equipment, machinery and stock? These items need to be stored safely and sensibly while the refurbishment work is underway, which incurs additional logistics costs. Moreover, it's not just a question of space - some machines or materials require specific storage conditions, such as a certain temperature or humidity, which are difficult to ensure during temporary relocation.

Cost explosion

A critical issue that business owners may face when modernizing their industrial floors is the risk of cost explosion. Without careful and detailed planning, unexpected expenses can arise that far exceed the original budget. This can be caused by a variety of factors, such as unforeseen difficulties in removing the old floor, delays due to supply shortages of materials or even the discovery of problems with the subfloor that were not apparent before work began.

Working with an experienced floor refurbishment partner is therefore crucial. Such a partner will not only bring years of experience to the table, but will also have in-depth knowledge of the materials and procedures necessary for successful completion. This expertise makes it possible to realistically estimate costs and create a budget that takes into account all aspects of the project - from material costs and labor hours to possible additional costs for unforeseen challenges.

It is therefore important to choose a service provider who not only provides a cost estimate, but also has a plan in place in case of unforeseen events. This plan should include measures on how to deal with surprises without breaking the budget and how to maintain flexibility in project planning to respond to such situations. Transparent communication, regular updates and open bookkeeping are also key elements to ensure that the budget remains controlled and cost escalation is avoided.

The solution in detail

Careful planning is essential to overcome these challenges. Choosing a PVC floor covering that can be laid quickly and without drying times is a first step. One way to minimize downtime is to divide the renovation work into sections so that only one part of the hall is affected at a time, while the rest remains operational.

The use of adhesives and materials that cure quickly is also important to reduce the time that the hall cannot be used.

For the clearing and storage of the facility, it is advisable to work with a logistics company that has experience in the temporary storage of industrial goods. This will ensure that all items are properly handled and stored while the renovation work takes place.

Renovating industrial floors

Industrial floor with a long service life, almost indestructible

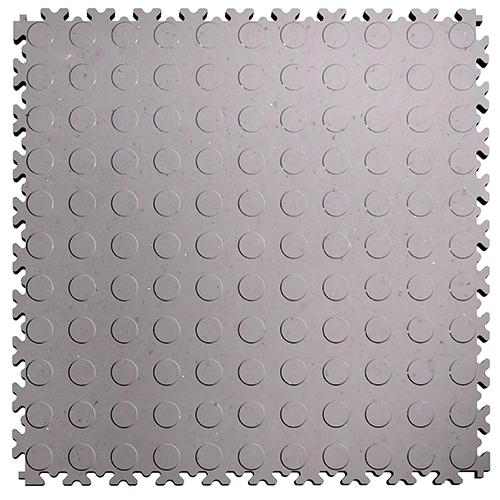

Durability: PVC floors are known for their long life and resistance to wear.Resistance: They are resistant to most chemicals, oils and other liquids commonly found in industrial environments.Easy installation: With the industrial floor click system, you can install the floor quickly and easily without the need for special tools. Even if damaged, they can be easily and inexpensively replaced, even during ongoing operations. Renovate on the fly: With PVC tiles, it is possible to renovate your facility even while it is in operation - an advantage that traditional tiles do not offer.Designs and colors: PVC tiles are available in a variety of designs and colors, allowing you to customize the floor to match your facility's design.

Why you should choose industrial PVC flooring

Industrial PVC flooring is not only practical but also cost effective. If you're thinking about buying industrial PVC flooring, consider the long-term benefits. Because of its durability and longevity, you won't have to replace the floor as often as other flooring options, which will save you money in the long run.

Where to buy cheap PVC industrial flooring?

If you are looking for a place to buy industrial flooring PVC cheap, you have come to the right place. Our online store offers a wide range of PVC flooring at competitive prices. Whether you are looking for a specific design, color or click system, we have what you need.

A PVC industrial floor is the ideal choice for any business that values safety, efficiency and aesthetics. With the many benefits that this flooring offers, it's no wonder that it has established itself as one of the best options for industrial businesses. If you are interested in purchasing a high-quality PVC floor for your business, visit our online store and discover the variety of our products.

Click tiles for industry

Industrial flooring: How to choose the right one for your requirements!

When choosing the right industrial floor, it is important to consider your specific needs and requirements. Some important factors include:

Traffic load: how much foot and vehicle traffic will the floor be exposed to on a daily basis?

Chemical resistance: will the floor come into contact with chemicals?

Slip resistance: How important is the prevention of slip hazards to employee safety?

Maintenance and cleaning: How often and how extensively will the floor need to be cleaned and maintained?

Cost: What is the budget for the floor?

Based on these factors, you can decide what type of flooring is best for your needs, such as epoxy floors for high chemical resistance or PVC floors for longer life.

It is also advisable to consider different flooring options and seek expert advice to ensure you choose the right flooring for your facility.

It is also important to carefully select flooring manufacturers and installers and check their credentials to ensure they have the necessary skills and experience to professionally and properly install the flooring.

Thorough planning and preparation can help the flooring last longer and reduce the total cost of ownership.

Tips and tricks for choosing the best PVC flooring for industrial applications

In the world of industrial flooring, PVC is a preferred choice due to its impressive blend of durability, resilience and ease of maintenance. This article sheds light on how to choose the best PVC flooring for your industrial applications by offering valuable insights and considerations.

Choosing PVC flooring for industrial environments is not just a question of aesthetics, but also of functionality. PVC floors are known for their ability to withstand extreme conditions. They are robust enough to withstand heavy foot traffic and the use of machinery without sacrificing quality. Another key benefit of PVC flooring is its chemical resistance. They offer reliable protection against various chemicals and oils, making them an ideal choice for many industrial applications.

In addition to robustness, ease of maintenance is a key factor that makes PVC flooring attractive. They are easy to clean and maintain, saving time and money in the long run. What's more, they are available in a variety of designs and colors, which means they can be not only functional but also aesthetically pleasing.

When choosing the right PVC flooring, you should consider the intensity of use. An area with high foot traffic or heavy machinery will require a more robust floor than areas with less foot traffic. Safety is another important consideration. Non-slip properties are crucial to ensure safety in the workplace, especially in areas where liquids can be spilled.

The installation of the PVC flooring is another important aspect. Professional installation ensures that the floor is laid optimally and can perform to its full potential. Regular maintenance is also crucial to maximize the life of the floor and ensure that it retains its aesthetic and functional properties in the long term.

Choosing the right PVC flooring for your industrial application can be a challenge, but with the right information and careful consideration, you can make a decision that balances safety, functionality and aesthetics. Visit our online store to discover our extensive range of PVC flooring for industrial applications and find the perfect solution for your needs.

Lay PVC industrial floors on problem floors

Clean PVC industrial floor properly

For more information, see:

PVC industrial tiles can be laid on almost any solid substrate.

The substrate does not have to be elaborately prepared or sanded flat. Oil stains do not need to be removed. In case of slight unevenness and damage, the floor does not need to be leveled.

A great advantage for companies is the lightning-fast installation and immediate 100% load-bearing capacity of the industrial floor.

If a PVC tile breaks, you can easily and quickly replace it with another one.

You do not need to hire a company and you do not have high follow-up costs.

The laying can be realized over night, also on weekends and during running operation (no stop of operation necessary).

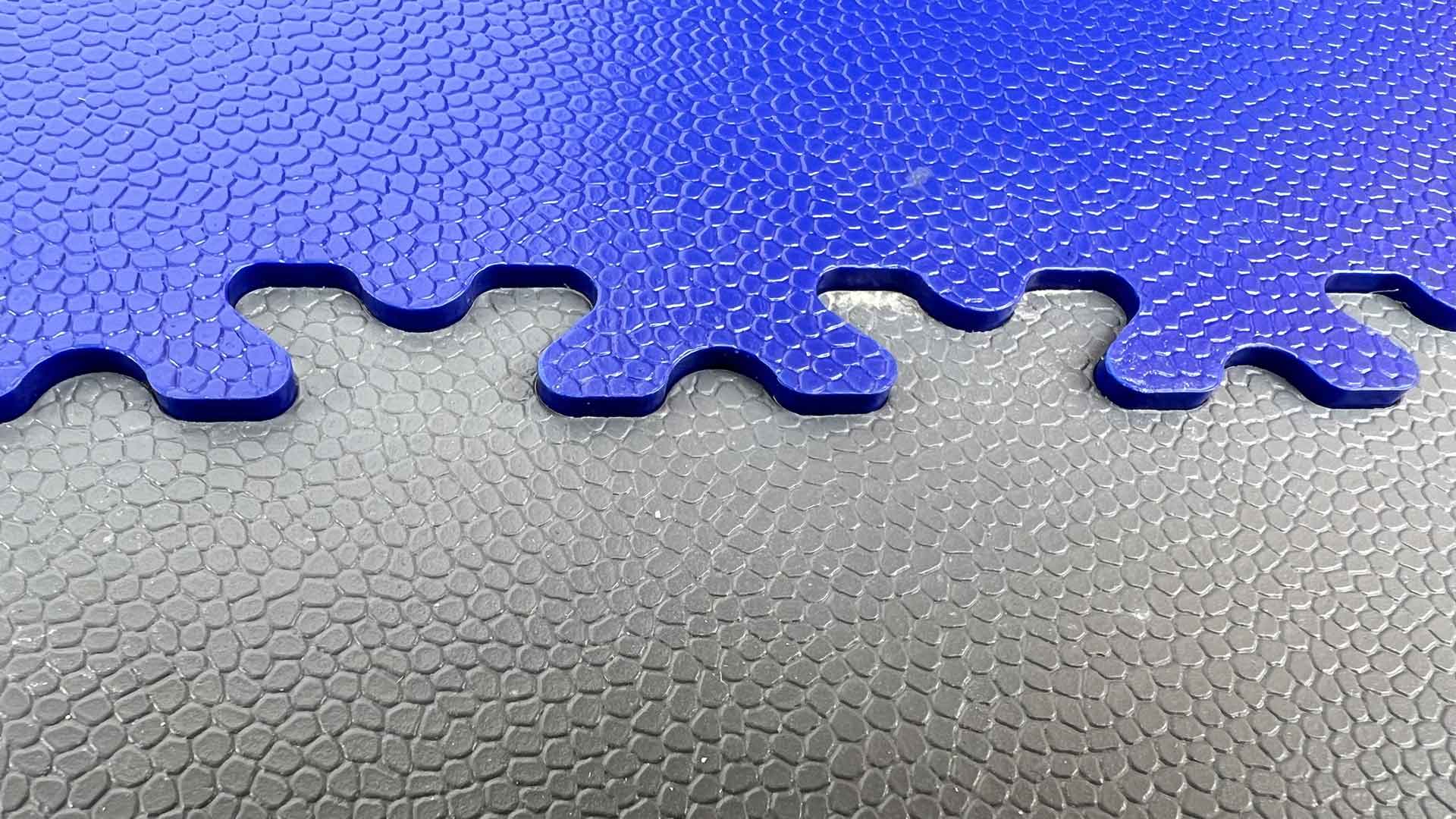

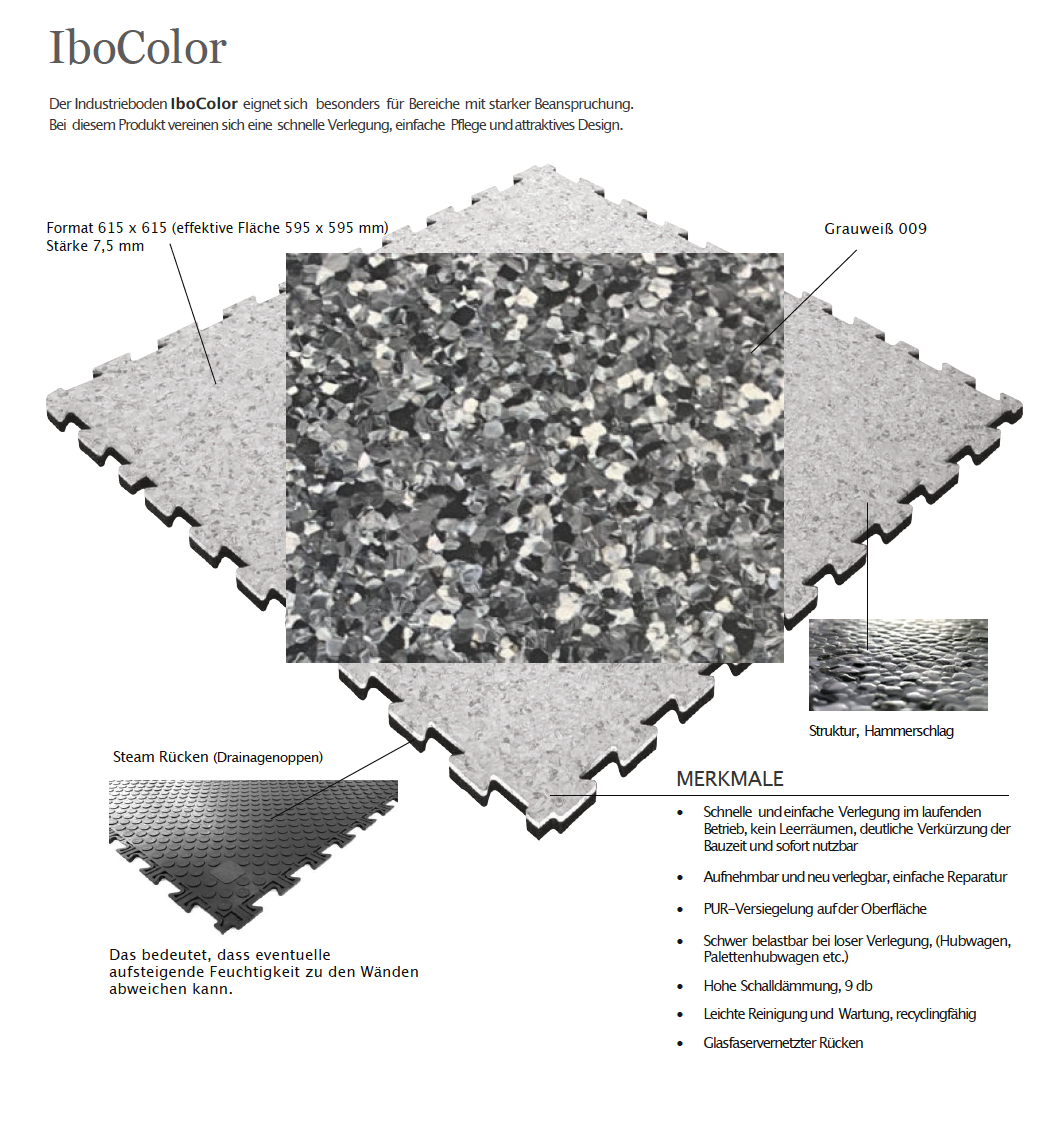

Due to their special properties, PVC tiles with click system from Fortelock are ideally suited as a surface for industrial floors. They have a low installation height of approx. 7 - 8 mm.

Fortelock PVC tiles are heat and sound insulating. Especially these properties are advantageous in industrial halls and workshops.

The sound development is significantly reduced and creates a pleasant working environment.

No expansion joint up to 2500 sqm.

Extremely long service life due to industrial quality. Almost indestructible, not even by heavy objects.

Advantages

- The floor is free of joints and flat

- A floor made of concrete is very robust

- Concrete is resistant

- Extremely durable

- Not combustible

Disadvantages

- Demolition of concrete floor is very expensive and difficult to dispose of.

- Concrete has an open-pored structure. As a result, it gets dirty quickly.

- It is very slippery when wet

- Concrete is not breathable and therefore does not absorb moisture from the air

|

Industrieboden |

Preis / m2* |

|

Schwerlast Fliese KLICK, flüssigkeitsdicht, 8 mm stark |

ab 49,80 € |

|

SCHWERLASTPLATTE Kreis102 43 mm stark |

ab 40,00 € |

|

Fortelock ECO ULTRA PVC Fliesen 10 mm stark |

ab 45,96 € |

|

Schwerlast Fliese Fast 7 mm stark |

ab 44,90 € |

|

Feinsteinzeug Klick Fliese PRO Indoor 28 mm stark |

ab 142,0 € |

|

Design Boden Stein 66X33 cm 8,2 mm stark |

ab 74,90 € |

|

Schwerlast Fliese STEP 8 mm stark |

ab 44,90 € |

|

Fortelock Industrie PVC Fliese Extra hart 7 mm stark |

ab 57,80 € |

|

Motorsport Fliesen Race 18 mm stark |

ab 36,95 € |

*The prices are in square meters, without guarantee (status: 01.10.2022)

Cost savings with PVC industrial floors: why they are worth a long-term investment

In the world of industrial flooring, the question of the most cost-effective solution often arises. PVC industrial flooring is an excellent choice in this context, offering not only immediate benefits but also proving to be a valuable long-term investment.

One of the main reasons why PVC flooring is a smart financial decision is its remarkable durability. Unlike other floor coverings that require frequent replacement or repair, PVC flooring will last for years, even under harsh industrial conditions. This resistance to wear, chemical substances and mechanical stress means that the need for frequent replacements or repairs is significantly reduced, resulting in considerable cost savings.

Another financial benefit of PVC flooring is its low maintenance. They are easy to clean and require no special cleaning agents or procedures. This ease of maintenance not only saves time, but also money, as fewer resources need to be spent on floor care.

The installation of PVC flooring is also a factor that contributes to long-term cost savings. Compared to other floor coverings, PVC installation is generally quicker and less expensive. This means that initial installation costs are lower and operations can resume more quickly, resulting in less downtime and associated costs.

The installation of PVC flooring requires less preparation time compared to other flooring types and can often be carried out overnight or during less busy periods. This means that halls and work areas do not have to be emptied or shut down for long periods of time. The ability to resurface the floor without major disruption to operations is particularly valuable for industries where every hour of downtime can mean significant financial loss.

In addition, the quick and easy installation of PVC flooring eliminates the cost and logistics of storing machinery and equipment. In many cases, areas of a hall can be renovated in stages while other parts remain in operation. This modular approach minimizes disruption and allows for continuous production or workflows.

PVC flooring also offers excellent adaptability to different industrial requirements. Their versatility in terms of design, texture and color makes it possible to create an environment that is both functional and aesthetically pleasing. This flexibility can have a positive impact on the working atmosphere and even help to increase employee productivity.

In conclusion, investing in PVC industrial flooring is a wise decision for any business looking for long-term cost efficiency. With their durability, low maintenance, cost-effective installation and versatility, they offer significant added value and help to reduce operating costs over time. Therefore, PVC flooring is not just an immediate solution, but a long-term investment that pays off.

Industrial floors for warehouses and production

Industrial floors are exposed to extreme loads day and night. Be it through high mechanical loads or chemical loads (oil, acidic liquids), approaching and braking forklifts and lift trucks. It is also exposed to physical stresses such as rolling, or abrasive stresses (e.g. settling of pallets, work processes ...) and temperature differences.

A conventional floor covering would not survive this continuous load.

Industrial flooring made of PVC tiles: Effects for the employees

PVC tiles industry cushion the movements and have a shock-absorbing and relieving effect on the spine and joints.

The performance of your workers is maintained longer.

Healthy walking and standing increases the well-being of your employees, reducing absenteeism.

Another great advantage of the click tiles!

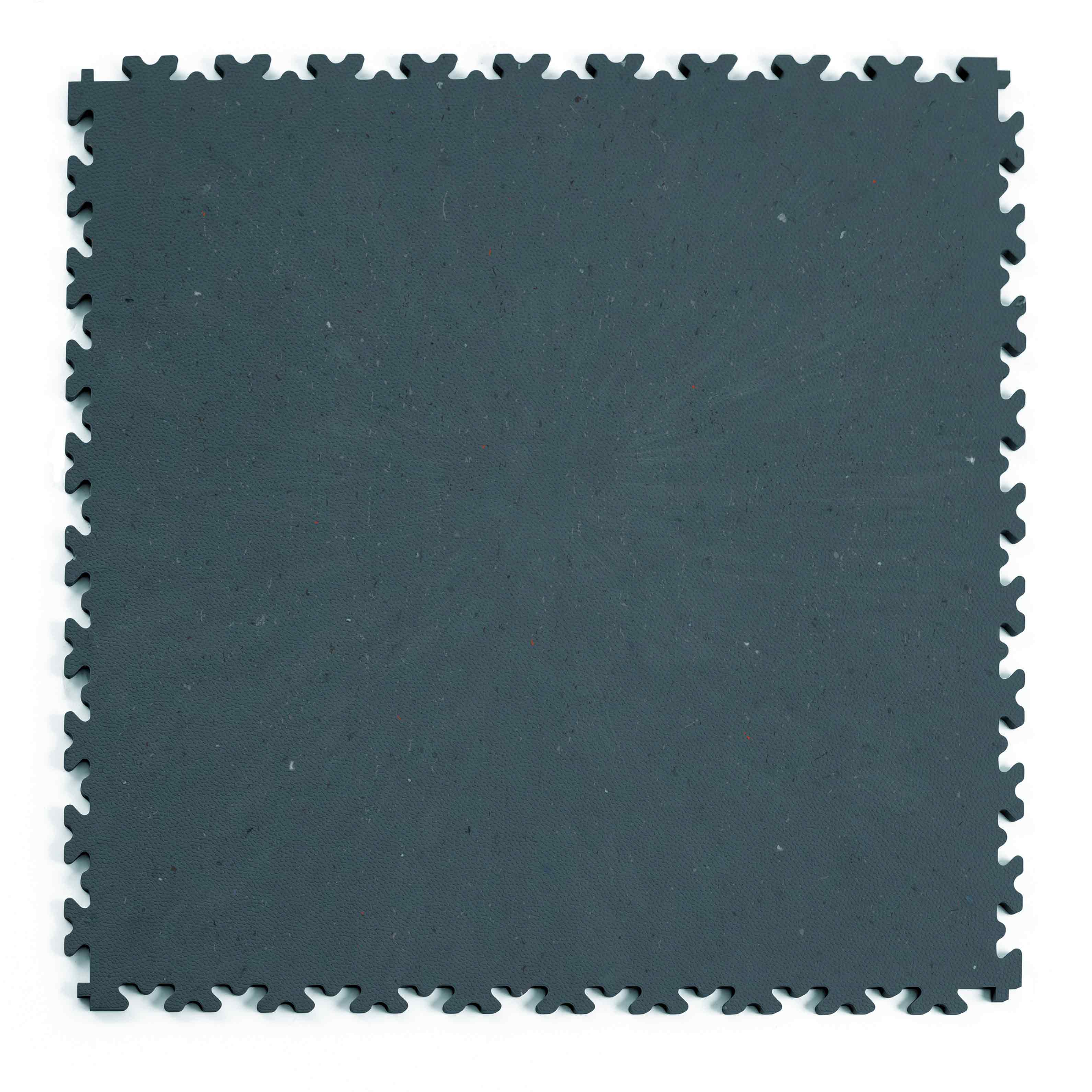

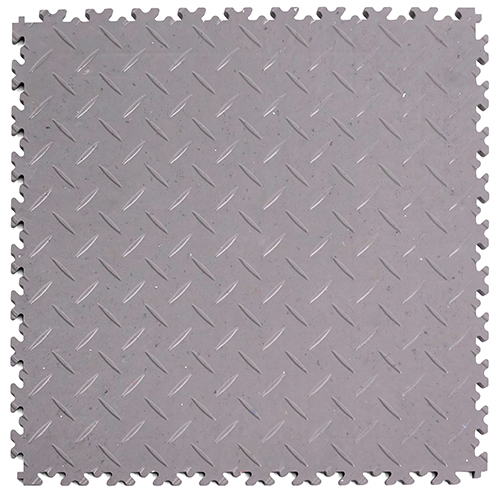

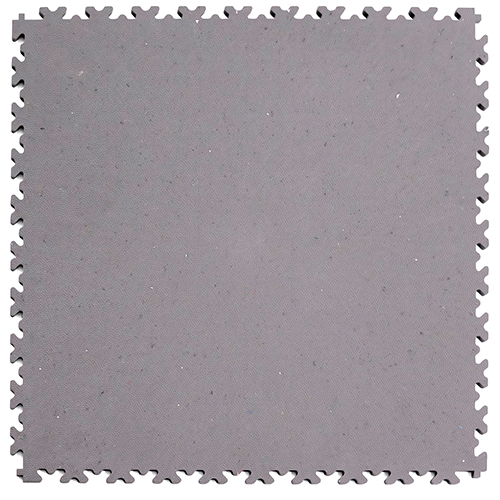

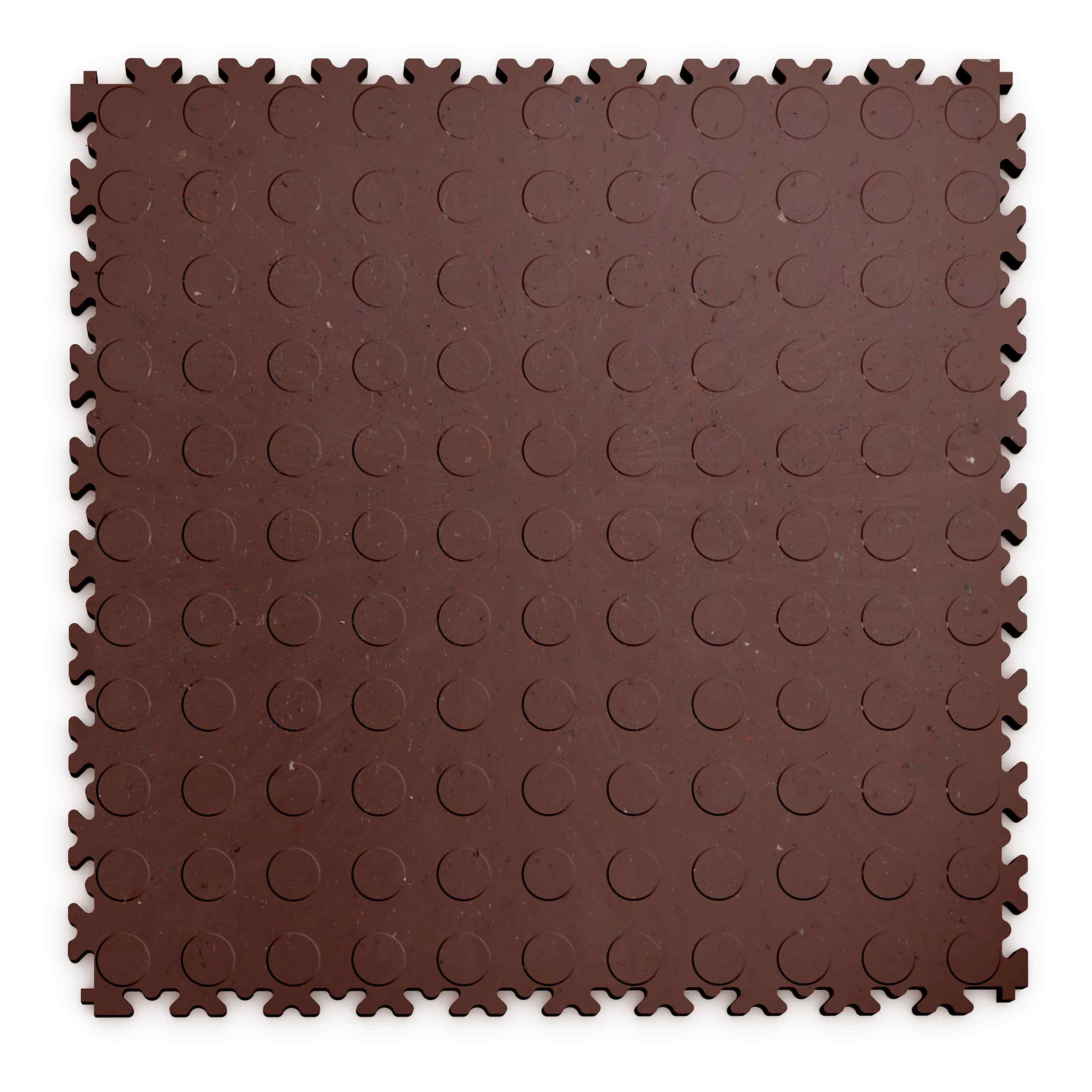

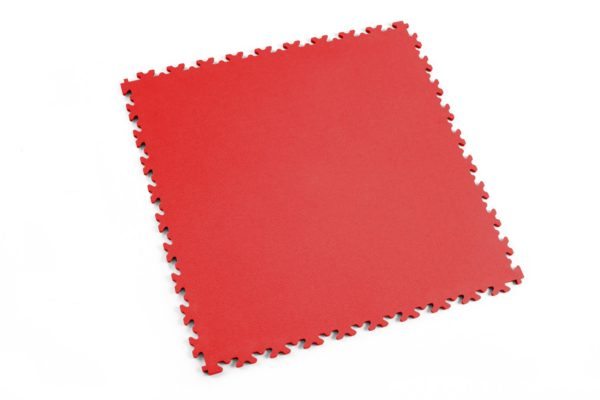

They can be expanded at any time. Through purchases new colors and finishes (leather, dots and diamond). The colors and finishes of PVC tiles industry can be combined with each other at will!

New work areas can be created. For example, electrical, red. Heating and plumbing blue.

Existing walkways and color-coded work areas can also be rearranged.

The industrial floor grows with your company and can be adapted according to your ideas.

You should also keep in mind, if you move with your company, you can easily take Fortelock PVC tiles with you. (If they were not glued)

Why industrial flooring is essential for factories and warehouses?

Industrial floors are essential in factories and warehouses because they are specifically designed to withstand the heavy loads imposed by heavy machinery, forklifts and other heavy equipment.

They are typically made of sturdy materials such as concrete, epoxy resin or polyurethane that are resistant to abrasion, chemicals, moisture and other potentially damaging elements.

They are also capable of increasing worker safety by providing a slip-resistant surface and minimizing the risk of slips or falls. In addition, they facilitate cleaning and maintenance, which contributes to a longer life of the floor, thus saving costs.

Driveway of the hall.

Laying and gluing, a hall with PVC

Hall completely laid and glued, with

How PVC industrial flooring can help improve occupational safety

In industrial environments, safety in the workplace is of paramount importance. PVC industrial flooring plays a crucial role in promoting this safety. Their unique properties help to minimize risks and create a safer working environment.

One of the main benefits of PVC flooring in terms of workplace safety is its slip resistance. In industrial areas where liquids can be spilled or where machinery and employees are constantly on the move, non-slip flooring significantly reduces the risk of slips and falls. PVC flooring can be provided with special surfaces and coatings that provide additional grip and thus increase safety for employees.

Another safety aspect of PVC flooring is its fire resistance. PVC materials are flame retardant and help to slow down the spread of fire. This is particularly important in industrial environments where the risk of fire can be increased due to machine operation or chemical substances.

The chemical resistance of PVC flooring is another factor that contributes to occupational safety. In industrial environments where aggressive chemicals are used, PVC flooring offers protection against corrosion and chemical damage. This ensures that the floor remains intact even under harsh conditions and poses no danger to employees.

PVC flooring also contributes to the general health and well-being of employees. They are dust repellent and easy to clean, which helps to reduce dust and allergens in the air. A clean and healthy working environment is crucial to protect the health of employees and reduce the risk of environmental health problems

Direct Sunlight

It is recommended to install the tiles in the places exposed to direct sunlight. These are mainly rooms with a lot of windows, areas facing south, light domes, etc. PVC tiles exposed to direct sunlight may heat up and expand faster than the rest of the floor.

HEAVY STACKERS AND STRONGLY AFFECTED AREAS

Some forklifts and lifting ants can damage the joints of Fortelock PVC tiles. These are, for example, heavy forklifts with small wheels (full rubber tires). Especially in the case of electric forklifts for heavy loads, where the battery is located above the drive axle. If you use this type of forklift. We recommend testing the tiles with the forklifts. Before deciding on what type of PVC tiles to use and whether to fix them.

Notice:

PVC tiles ECO expand more than PVC tiles industry.

HEAT SOURCES, CATALYSTS and Ovens

Can heat the floor strongly, causing expansion of the tiles? To avoid such a process, you should glue the tiles in the area of the heat source. Be it in front of ovens, or where a parked vehicle acts as a catalyst or where there is another heat source.

Note: In case of uneven surfaces and/or when using tiles made of recycled materials, the maximum load may be lower.

Notice:

For halls with larger driveways or in areas where heavy vehicles are used, we advise bonding the PVC tiles approximately 1.5 m from the driveways towards the center of the hall.

hall floor

Workshop floor

industrial floor

The heavy-duty floor prevents water and other liquids from penetrating the floor. This prevents contamination and facilitates e.g. cleaning and keeping the floor clean.

Can be driven over with 5 tons without bonding the heavy-duty floor to the subfloor! Full-surface glued, loadable up to 45 tons!

For forklifts, ants, cars and trucks. To lay the heavy-duty PVC floor floating means that the PVC heavy-duty tiles have no connection to the subfloor. There are also only the PVC heavy-duty tiles connected by the click system. The PVC heavy-duty floor is not fixed anywhere and lies loosely on the subfloor.

Innovations in the PVC industrial flooring sector: a look into the future

The PVC industrial flooring industry is on the cusp of an exciting future, characterized by significant innovations and technological advancements. These developments are aimed at improving the efficiency, sustainability and aesthetics of PVC flooring to meet the dynamic demands of modern industrial environments.

A key trend in the industry is the growing awareness of environmental sustainability. Manufacturers are striving to develop more environmentally friendly products by using recycled materials and exploring PVC alternatives that have a lower environmental impact. In parallel, there is a focus on improving the durability and performance of PVC flooring. The aim is to create products that are even more resistant to abrasion, chemicals and mechanical stress, which is particularly important in demanding industrial environments.

The integration of technology into flooring is another exciting trend. The idea that sensors could be embedded into PVC flooring to collect important data opens a new chapter in the flooring industry. These smart flooring technologies could provide valuable insights into traffic flows and wear patterns, helping to drive preventative maintenance and increase efficiency

At the same time, we are seeing a revolution in design options for PVC flooring. Thanks to advances in printing and manufacturing technologies, PVC flooring will be available in an ever-increasing variety of designs and textures, allowing for more customized and aesthetically pleasing work environments.

Not forgetting the improvements in health and safety. The development of PVC flooring that helps improve air quality or has antibacterial properties is a crucial step in promoting healthier working environments and preventing the spread of pathogens.

Finally, simplifying installation and maintenance is an important aspect of future development. New compositions and designs of PVC flooring that allow for faster and more cost-effective installation will revolutionize the way industrial flooring is installed and maintained.

Overall, the PVC industrial flooring industry is facing a future characterized by innovations that will not only change the production methods and use of industrial flooring, but also help to make working environments safer, more efficient and more pleasant.

Helpful guides:

Schwerlastfliesen als schnelle Lösung für die Werkhallengestaltung

Möglichkeiten zur Sanierung von Ölflecken auf Betonböden

Anleitung zum Verlegen für Größe Hallen

Klick Fliesen verlegen: Darauf sollten sie achten

Verlege Anleitung für Motorsport Fliesen

Vor- und Nachteile, einer schwimmenden Verlegung von Klick-Fliesen

PVC-Fliesen als Bodenbelag hinter Fensterfronten - Eine Herausforderung?

PVC Boden Preis: Alle Kosten erklärt

FAQ Industrial floor

Workshops, production halls of all kinds, warehouses, mechanical engineering, the automotive and vehicle industry, car dealerships, large-scale industry... It doesn't always have to be used in industrial facilities, a lot is also demanded of the floor in public buildings, hotels, banks, large-scale retail outlets, exhibition halls, sports studios, classic car garages....

While PVC tiles can be laid with little effort and by a DIY enthusiast. Coating with epoxy resin is very demanding and involves risks. It is advisable to have this carried out by specialist companies.

Designing an industrial floor with tiles of different colors is an innovative idea that combines functionality and aesthetics in a unique way. In today's world, where the appearance of a workplace is just as important as its functionality, such a floor offers an ideal solution.

The use of different colored tiles in industrial environments goes beyond mere aesthetics. It can help to define different areas within a facility, making it easier to navigate and contributing to workplace safety. Colors can be used to designate specific zones, such as walkways, hazardous areas or specific workstations. This not only improves efficiency, but also increases safety by providing clear visual cues for employees.

When

deciding how PVC tiles should look, it is important to consider the specific

requirements and conditions of the industrial area in question. In areas with

high foot traffic or heavy machinery, durability and slip resistance should be

a priority. Here, PVC tiles with a stronger texture and in darker colors that

make dirt and wear marks less visible can be a smart choice.

In the world of industrial flooring, there are a variety of options, each offering specific properties and benefits. These different flooring options are designed to meet the diverse requirements of different industrial environments. Here are some of the most common types of industrial flooring:

PVC flooring: PVC (polyvinyl chloride) is a popular material for industrial flooring because it is durable, easy to clean and resistant to chemicals, oils and other substances. PVC flooring is often available in tile or roll form and can be designed in a variety of colors and patterns.

Epoxy resin floors: Epoxy resin floors are made from a combination of resins and hardeners that form an extremely hard and durable surface. They are ideal for areas where high durability and easy cleaning are required, such as workshops, warehouses or factories

Concrete floors: Concrete is a traditional material for industrial floors. It is very robust and suitable for areas with heavy traffic and machine use. Concrete floors can be sealed or treated with special coatings for added protection and easier cleaning.

Rubber flooring: Rubber is another material commonly used in industrial environments. It offers good slip resistance and cushioning, making it ideal for areas where employees stand for long periods or delicate items are handled.

Ceramic or stone tiles: This type of flooring is often used in areas where aesthetics play a role. Ceramic and stone tiles are durable and easy to clean, however they can be slippery in damp environments and are less impact resistant than other materials.

Antistatic floors (ESD floors): Anti-static floors are essential in areas where sensitive electronic equipment is handled. These floors prevent the accumulation of static electricity and thus protect the equipment from damage.

Linoleum flooring: Linoleum is an environmentally friendly option made from natural materials such as linseed oil, resin, limestone and jute. It is hard-wearing and easy to clean, making it a good choice for many industrial environments.

Before installing PVC tiles on a dirty or damp subfloor, it is important to carry out thorough subfloor preparation. This may include cleaning and drying the subfloor to ensure that no moisture is trapped under the tiles. In some cases, it may be necessary to apply a moisture barrier or a special primer to prevent long-term problems