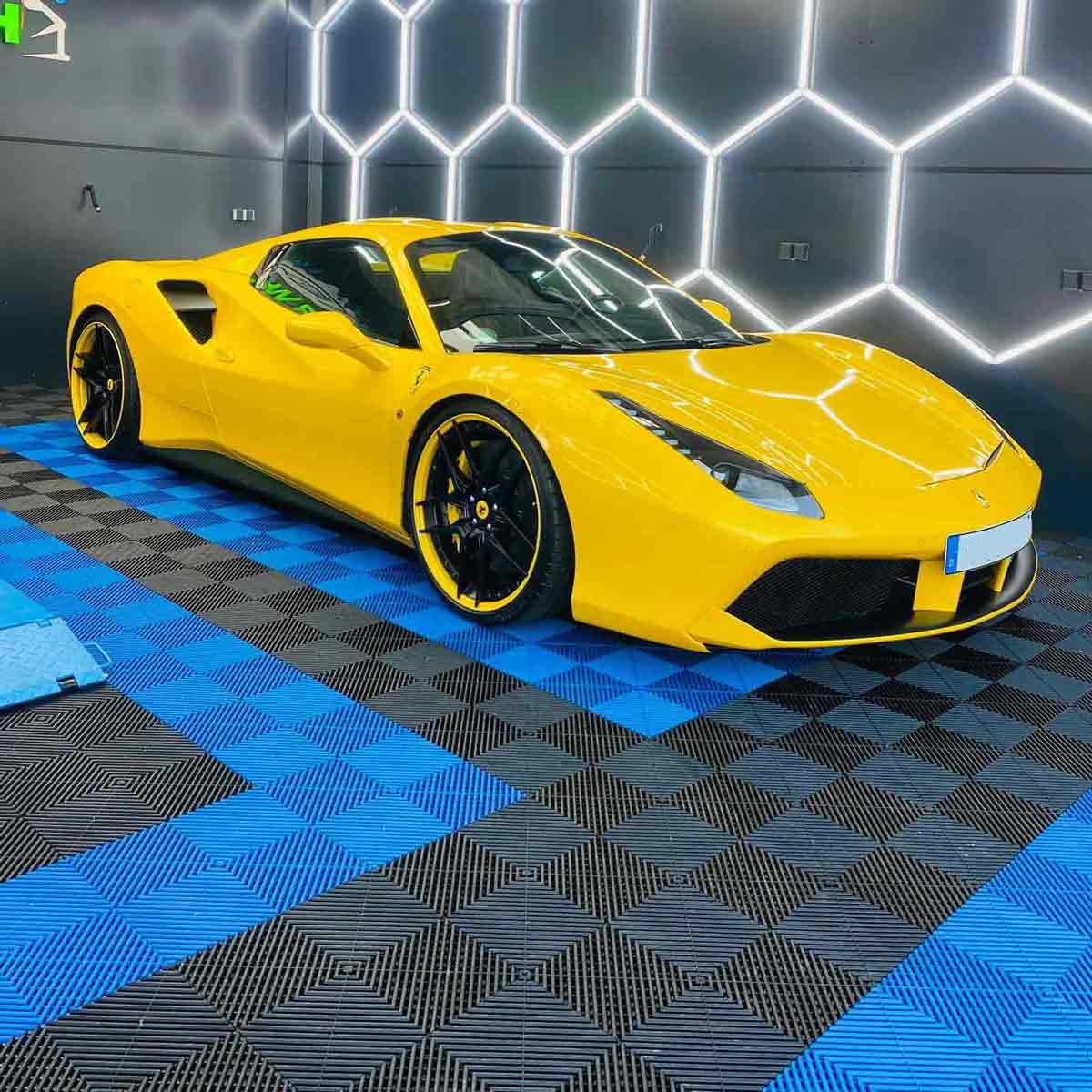

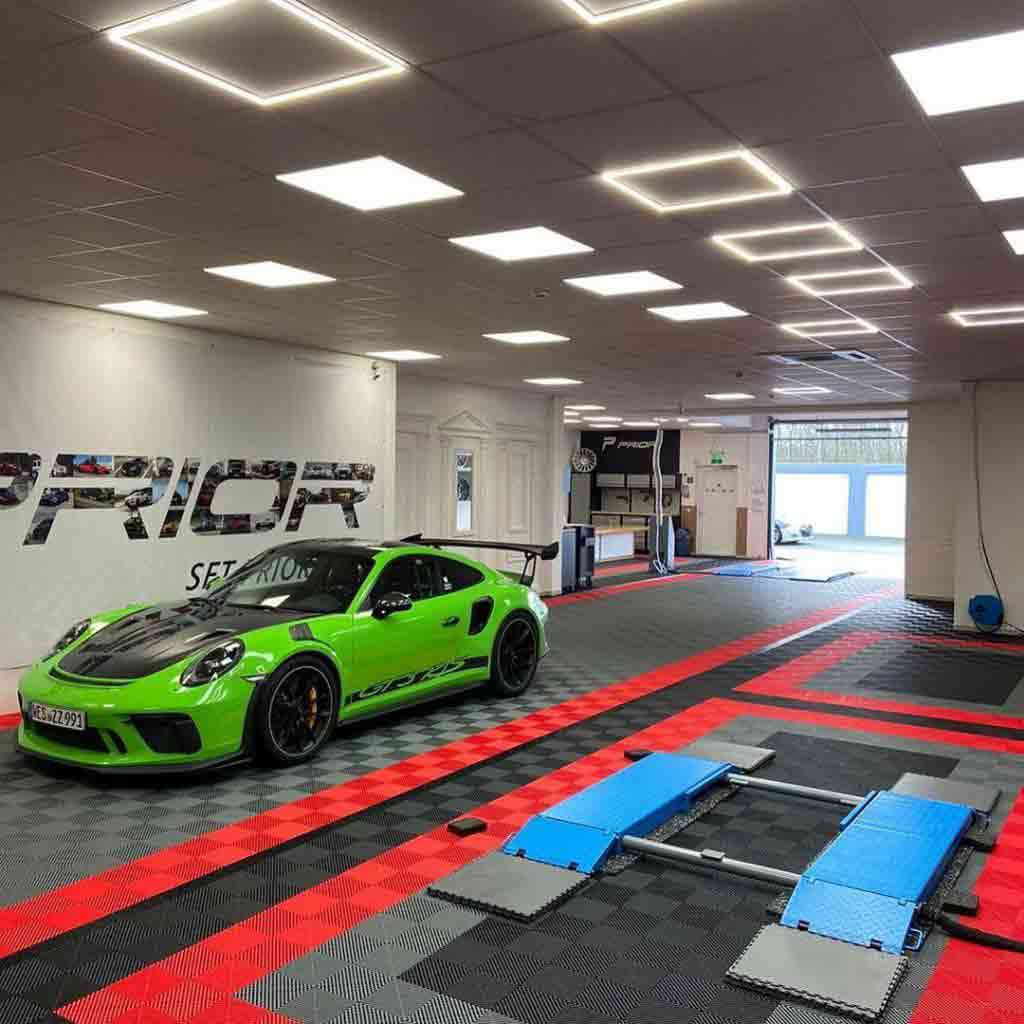

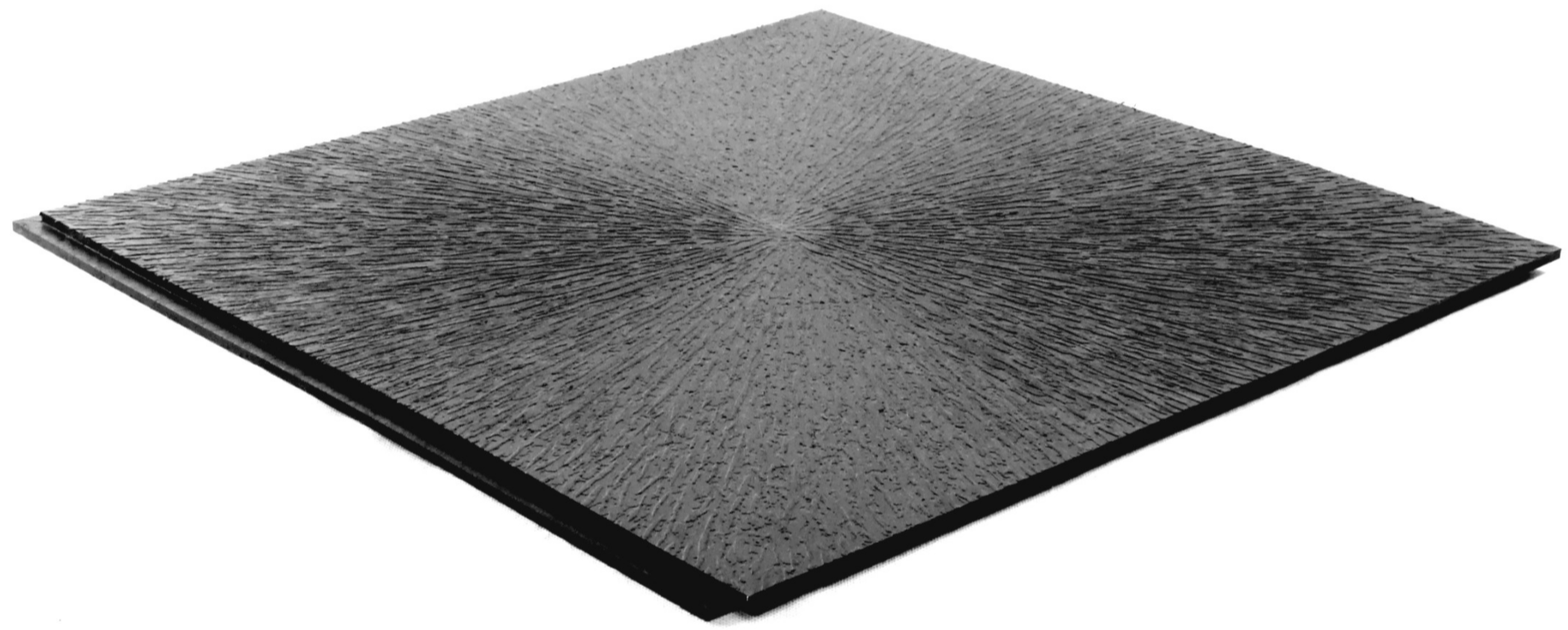

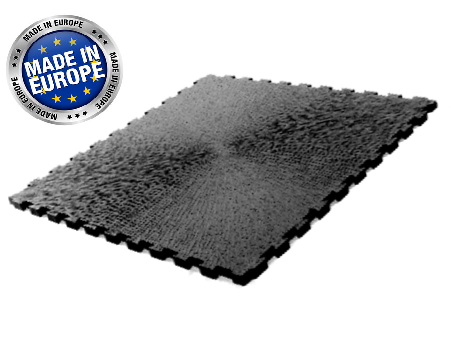

Heavy duty tile STEP 8 - 12.5 mm

€50.90*

Net: €42.77Free shipping

Available in 1 day, delivery time 5-6 weeks

Heavy duty tile STEP

Industrial floor, liquid-tight and can be driven on with 5 tons without gluing the heavy-duty floor to the subsoil! Fully bonded up to 45 tons

You cannot buy this article in a shop or hardware store!

The industrial floor is made of high-quality PVC recycling material and is therefore durable

It is resistant to almost all alkalis, fats, acids and oils.

The weld seam is already worked into the heavy-duty PVC STEP tiles. The heavy-duty tiles must always be thermally welded with welding cord

comes in 3 strengths

Dimensions: 49cm x 49cm x 8mm

Dimensions: 49cm x 49cm x 10mm

Dimensions: 49cm x 49cm x 12.5mm

black 9001* dark gray 7012* gray 7045*

*similar to RAL

In tree bark structure (slip resistance R11) and smooth surface (slip resistance R9).

Advantages of the heavy-duty floor that can be driven on by forklifts

- With floating installation, can be driven on with a forklift truck up to 5 tons without gluing

- Liquid-tight installation possible without gluing the industrial floor to the subsurface

- Lightning-fast installation and immediate 100% resilience of the heavy-duty floor.

- Relocations overnight, including weekends, during ongoing operations (no operational stoppages) and in sections are possible.

- Laying on problem floors (oil, cracks and damage)

- Protects your products and tools, heavy-duty PVC tiles have a shock-absorbing effect.

- Large and heavy production machines can be placed on it

- easy and quick replacement of damaged PVC heavy-duty tiles

- A shock-absorbing and relieving effect on the spine and joints.

- The PVC heavy-duty tiles are very easy to keep clean and are suitable for machine cleaning.

- Bonded over the entire surface, can be loaded up to 45 tons

- EU branded product

- Well suited for industrial areas, fire stations, logistics, car workshops, etc.

|

TECHNICAL SPECIFICATIONS |

|||

|

STRESS |

|||

In tree bark structure (slip resistance R11) and smooth surface (slip resistance R9) |

|||

|

TECHNICAL CHARACTERISTICS |

STANDARD |

VALUE |

|

|

stress class |

EN685 |

34-43 |

|

|

overall thickness |

EN428 |

7-10mm |

|

|

hardness |

ISO 868 |

92-94 |

|

|

Resteindruck |

EN433 |

0.08 |

|

|

abrasion |

EN660-2 |

417 |

|

|

RESISTANCE TO CHEMICALS |

|||

|

machine oil |

No change in the sample material after 72 hours |

||

|

acetic acid |

|||

|

Sulfuric acid 1:1 |

|||

|

Potassium Hydroxide 10% |

|||

|

toluene |

|||

|

CE mark - EN 14041 |

|||

|

TECHNICAL CHARACTERISTICS |

STANDARD |

VALUE |

|

|

sliding resistance |

EN 13893 |

DS |

|

|

room for change |

EN 13553 |

below the classification limit (1.8cm³ /dm³) |

|

|

reaction to fire |

EN 13501-1 |

Bfl-s1 (B1) |

|

|

VOC (qualitative) |

EN 17025 |

passed |

|

|

Pentachlorphenol |

EN 17025 |

<0.1 mg/kg passed |

|

|

VOC emissions |

DiBt |

passed |

|

|

Antistatic under standard conditions (25% relative humidity below 25°C room temperature) |

IN 1815 |

4.4KV (not met) |

|

|

Antistatic under everyday conditions (50% relative humidity below 25°C room temperature) |

IN 1815 |

1.8KV (meet) |

|

|

Heat transfer resistance (suitability for underfloor heating) |

EN 14041:2004 |

0.07 m²k/W (fulfilled) |

|

|

total weight |

EN430 |

10mm-15kg; 7mm-11kg |

|

|

plate size |

490 mm x 490 mm |

||

|

Tested at: |

|||

|

TFI Textiles & Flooring Institute GmbH Aachen |

|||

|

IMS AD Belgrade Institute for Material Testing |

|||

| Anzahl pro m²: | 4 |

|---|---|

| Befahrbar mit Hubwagen und Ameisen: | Geeignet für Hubwagen und Gabelstapler, Wenn der Boden Fixiert oder verklebt wird, lässt sich die Belastung um ein Vielfaches erhöhen |

| Einsatzbereiche: | Einzelhandel (Lebensmittel-Einzelhandel), Gewerbeboden, Werkstattboden, Werkstätten mit nassem Betrieb |

| Gewicht Pro Fliese: | 8mm - 11Kg / m², 10mm - 15 Kg / m² |

| Material der Fliese: | PVC |

| Verlege maß pro Fliese: | 490 x 490mm |

| slip class : | Tree bark R11, glatte Oberfläche R9 |

| strength : | 8 mm, 10 mm, 12,5 mm |

| surface : | Baumrinde R11, Glatte Struktur |

Login

| File | Category | Size | Filetype | Prio |

|---|---|---|---|---|

| Gesamtkatalog | Kataloge | 2.79 MB |

It is possible that PVC tiles from different production batches have color variations. Therefore, to ensure a uniform laying pattern and flooring, it is recommended to place the required number of tiles in a single order. It is advisable to plan for a 5-10% off cut

Can be driven over by up to 5 tons when laid as a floating system

Glued loadable up to 45 tons

A great advantage for companies is the lightning-fast installation and immediate 100% load-bearing capacity of the industrial floor.

Installation on problematic floors (oil, cracks and damage)

You do not need foreign companies

The PVC heavy-duty tiles cushion the movements and have a shock-absorbing and relieving effect on the spine and joints

Sound reduction in very noisy workplaces, for example production or warehouse operation.

Protects your products and tools if something should shut them down

Advantages of a cheap renovation, the workshop floor with PVC tiles

It is not necessary to prepare the subsurface in a time-consuming manner or to grind it flat,

Oil stains do not need to be removed. If there are slight bumps, damage or small cracks, the workshop floor does not need to be leveled out. Simply remove loose parts, vacuum the workshop floor and start laying

PVC tiles Fortelock Industrie ECO can be laid on almost any

solid surface.

The substrate does not have to be prepared in a time-consuming manner or sanded flat. Oil stains do not need to be removed. In the case of slight unevenness and damage, the floor does not have to be leveled.

A big advantage for companies is the lightning-fast installation and immediate 100% resilience of the industrial floor.