Hybrid 1-K Grout

€19.30*

Net: €16.22Available, delivery time: 1-2 weeks

Special joint compound hybrid 1-component joint compound

We recommend this product for heavy-duty click tiles.

With the Hybrid 1-K joint compound you get a moisture-proof covering without having to thermally weld!

for gluing and sealing the click coverings, for inside and outside

adheres to damp surfaces

The joint compound 1-K is enough to glue around 20 square meters.

Login

2 October 2022 08:41

Gutes Produkt

Sehr handlich und gut zu dosieren, immer wieder!

| File | Category | Size | Filetype | Prio |

|---|---|---|---|---|

| Gesamtkatalog | Kataloge | 2.79 MB |

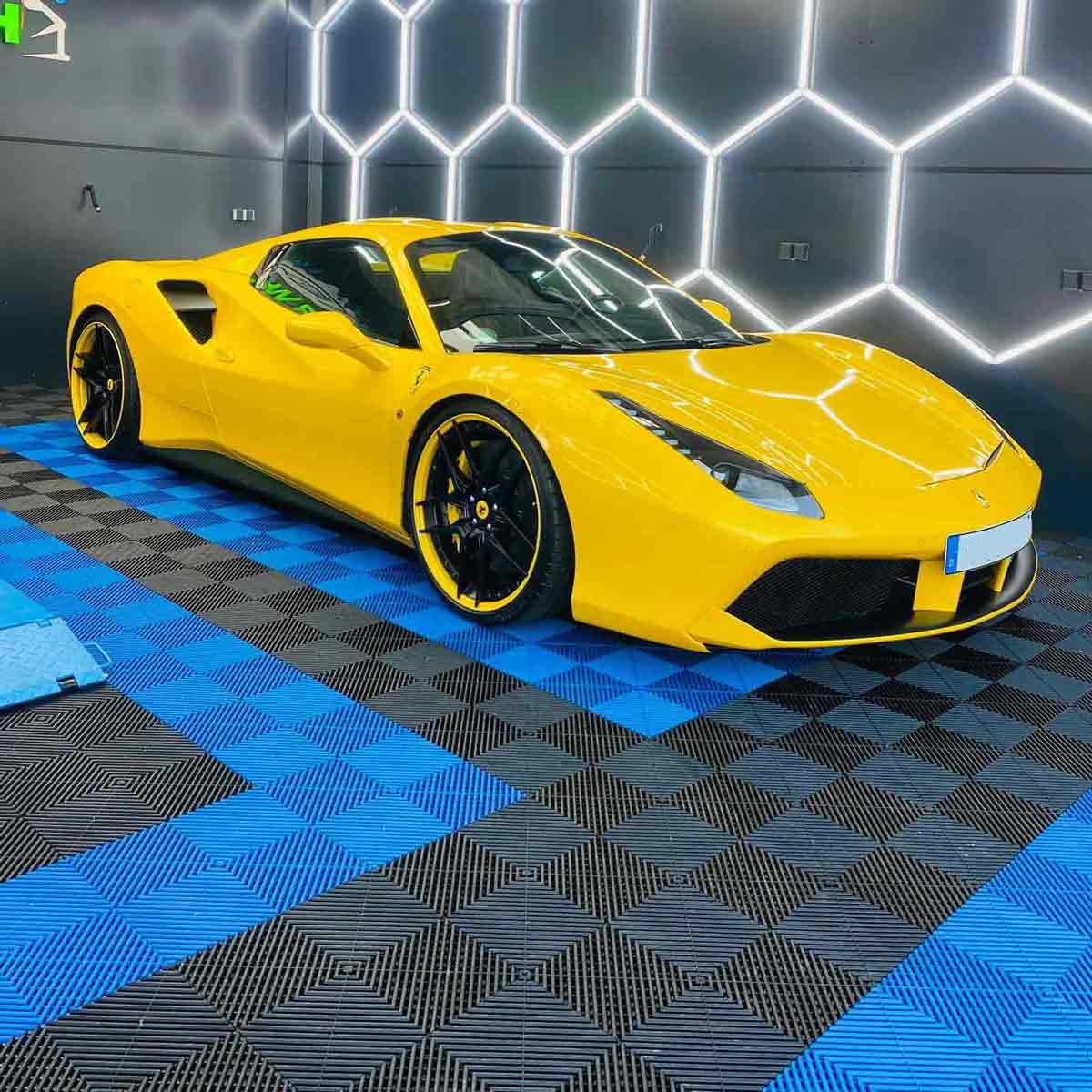

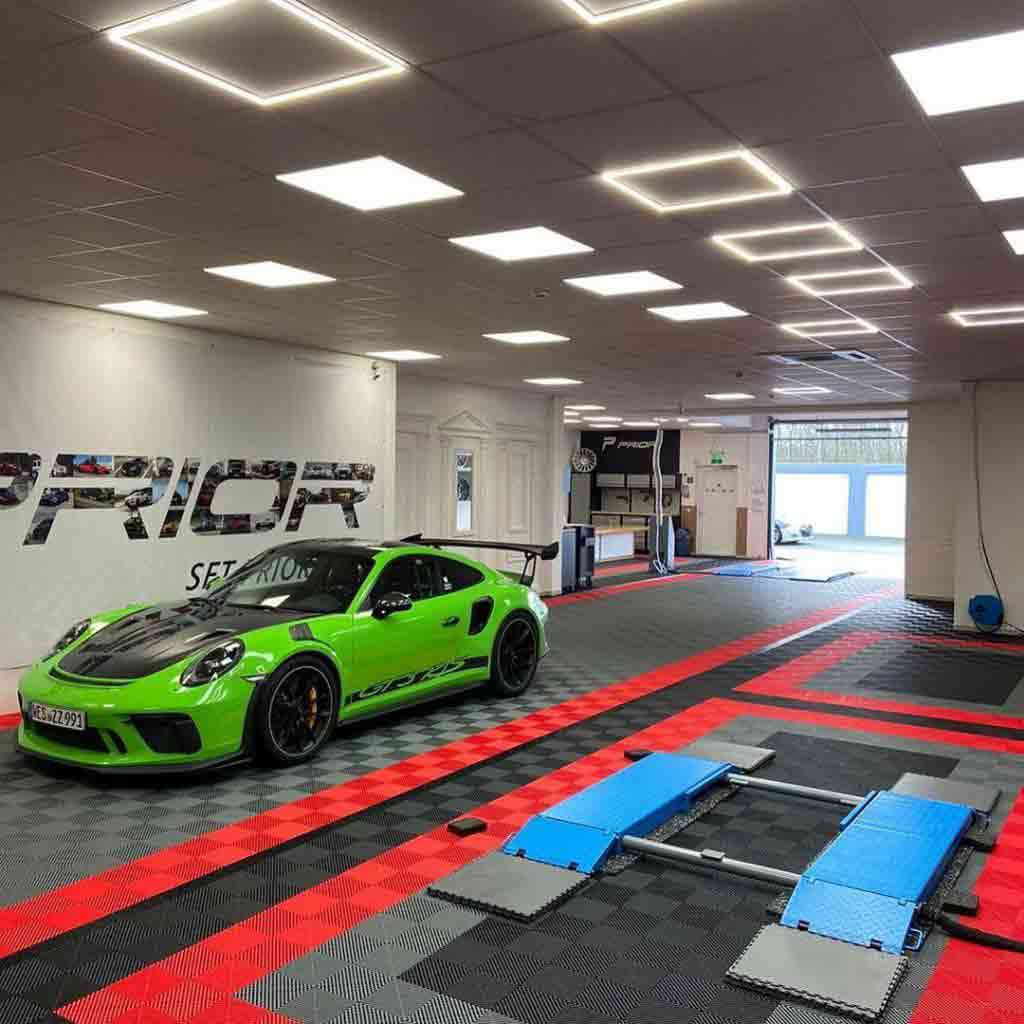

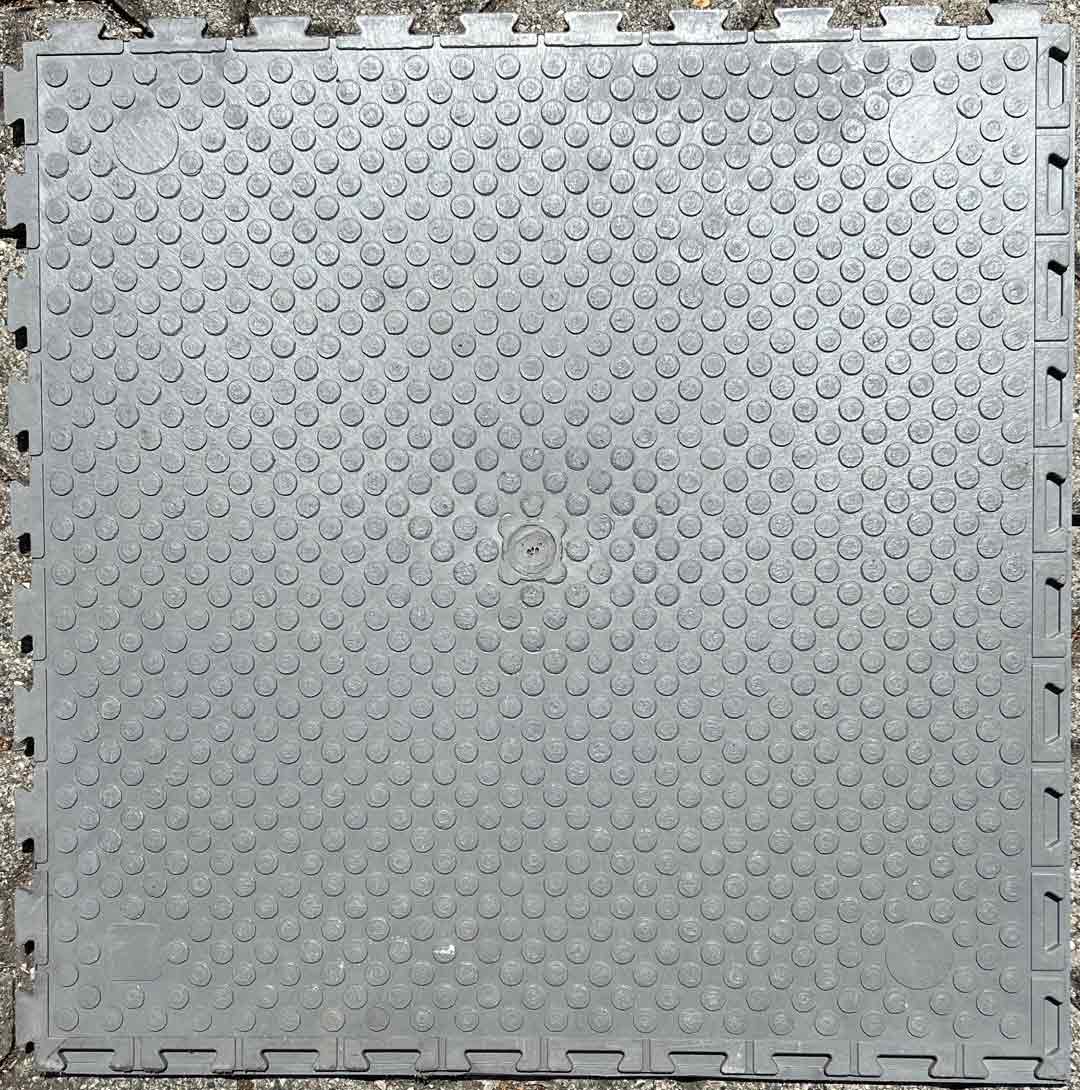

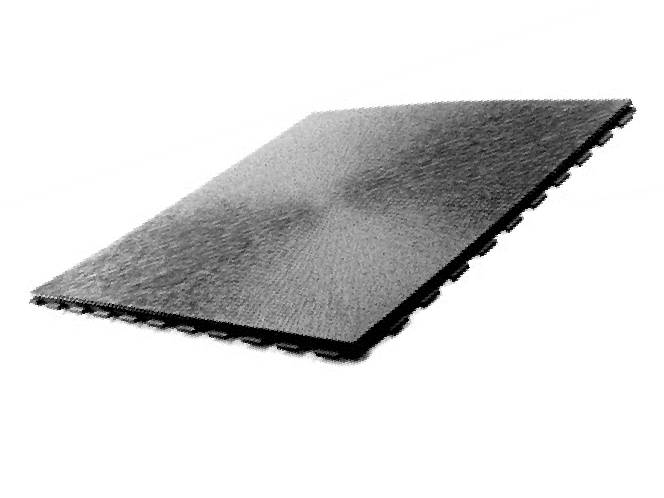

Glatte Oberfläche (Rutschfestigkeit R9)

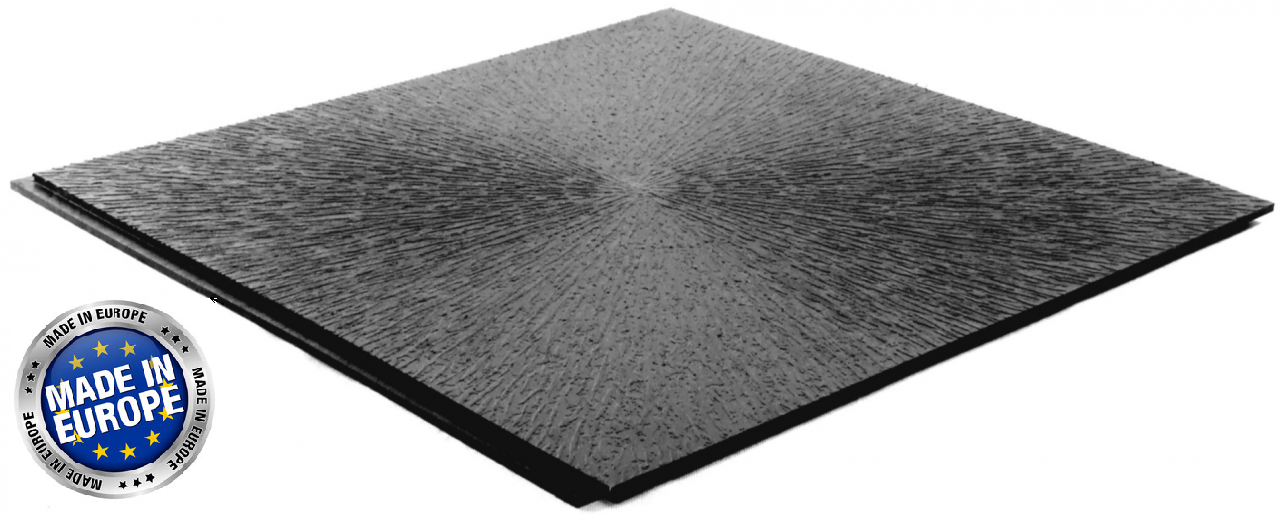

Baumrinde Struktur (Rutschfestigkeit R11)

It is possible that PVC tiles from different production batches have color variations. Therefore, to ensure a uniform laying pattern and flooring, it is recommended to place the required number of tiles in a single order. It is advisable to plan for a 5-10% offcut

With floating installation, up to 5 tons can be driven on

Glued up to 45 tons loadable

Resistant to oils, fats and chemicals

A big advantage for companies is the lightning-fast installation and immediate 100% resilience of the industrial floor.

Laying on problem floors (oil, cracks and damage)

You don't need any other companies

The PVC heavy-duty tiles cushion movements and have a shock-absorbing and relieving effect on the spine and joints

Noise reduction in very noisy workplaces, for example production or warehouse operations.

Protects your products and tools if something should shut them down

PVC tiles Fortelock Industrie ECO can be laid on almost any solid surface.