How can you repair PVC tiles?

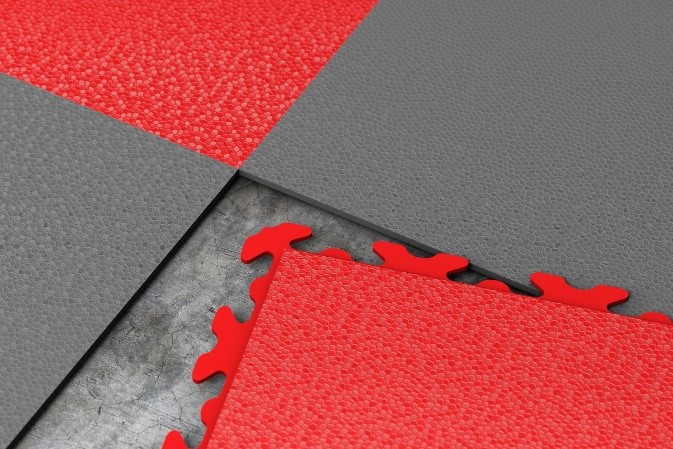

A crack in a PVC floor or a small hole can quickly appear. It only needs to drop a cup once and the mishap is there. Even with a small hole, moisture and moisture can penetrate under the floor covering. You don't have to replace the PVC floor completely, but can repair it with simple means. Cold welding of PVC flooring is the right solution in such a case.

All you need is a special adhesive that is especially suitable for PVC. However, you can also find so-called repair sticks in stores. These resemble a silicone-like mass. However, you cannot use direct silicone to repair PVC floors, this is not suitable because it does not have sufficient durability.

How do you remove fully taped PVC flooring?

Would you like to cold-weld PVC floors? Then the underground must first be freed from the old floor, but what is the quickest way to do this without leaving any residue? The effort involved in removing the old PVC floor is certainly due to the attachment. Of course, the subsequent use also plays a major role. Fully glued floors are certainly the most difficult to remove. If a new floor is to be applied after removal, a rough removal of the adhesive residue is sufficient in most cases. You should know that with PVC tiles, PVC cold welding usually takes place at five points. This gives this floor covering its permanent strength. Be careful when removing it.

PVC cold welding, also possible at low temperatures?

PVC floor cold welding is also possible at low temperatures without any problems. However, it is important that the temperature does not fall below 5 degrees. If the temperature falls below 5 degrees, condensation can collect on the adhesive film. A so-called pseudo connection can occur, which is not noticeable at the beginning, but only when the floor is loaded. Consumers keep asking themselves whether they need to wear protective clothing when using adhesive if they want to lay PVC flooring. Optimal protection is certainly advisable and you should therefore always observe the safety instructions for the respective product.

Swell:

https://www.tedox.de/blog/renovieren/pvc-kaltverweissen/