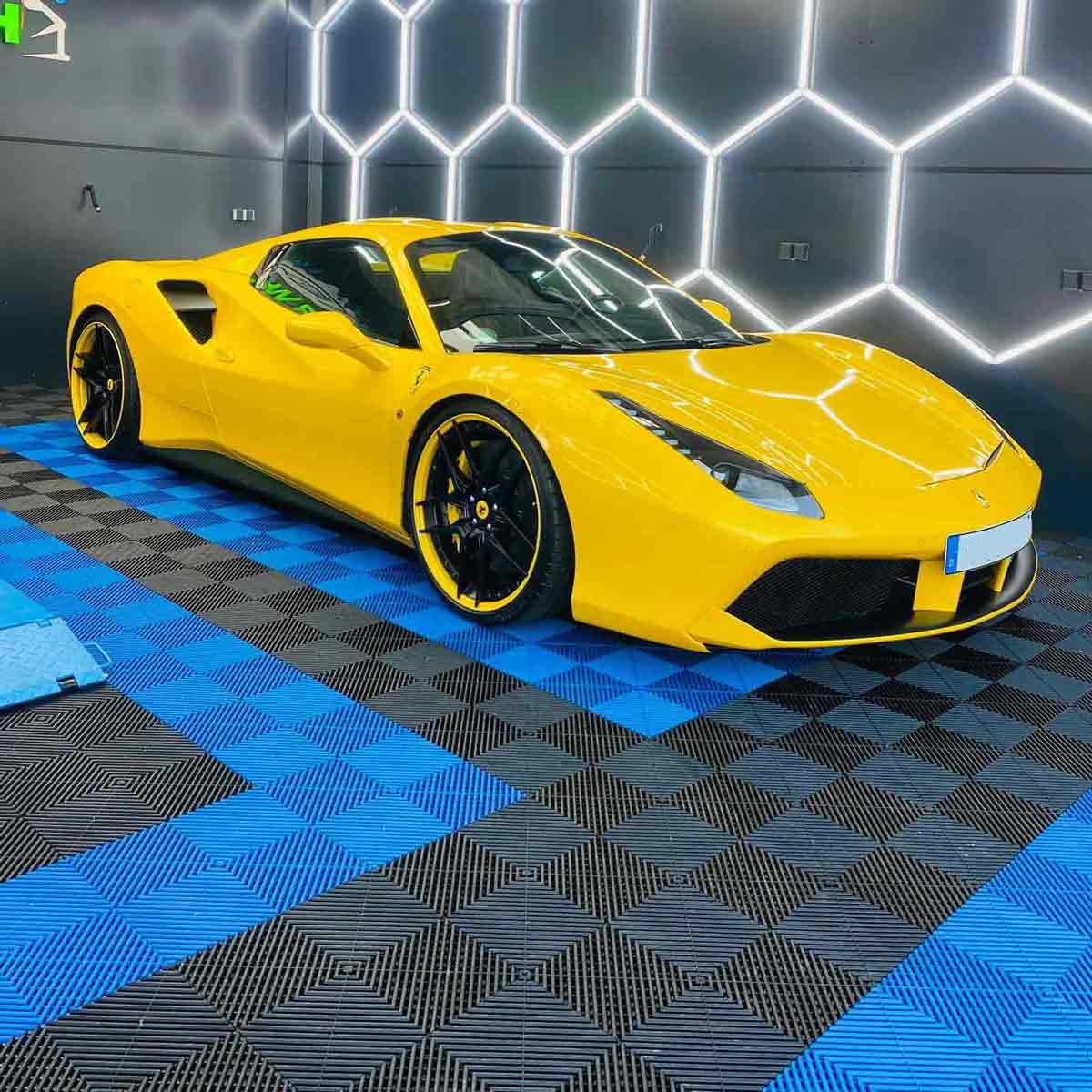

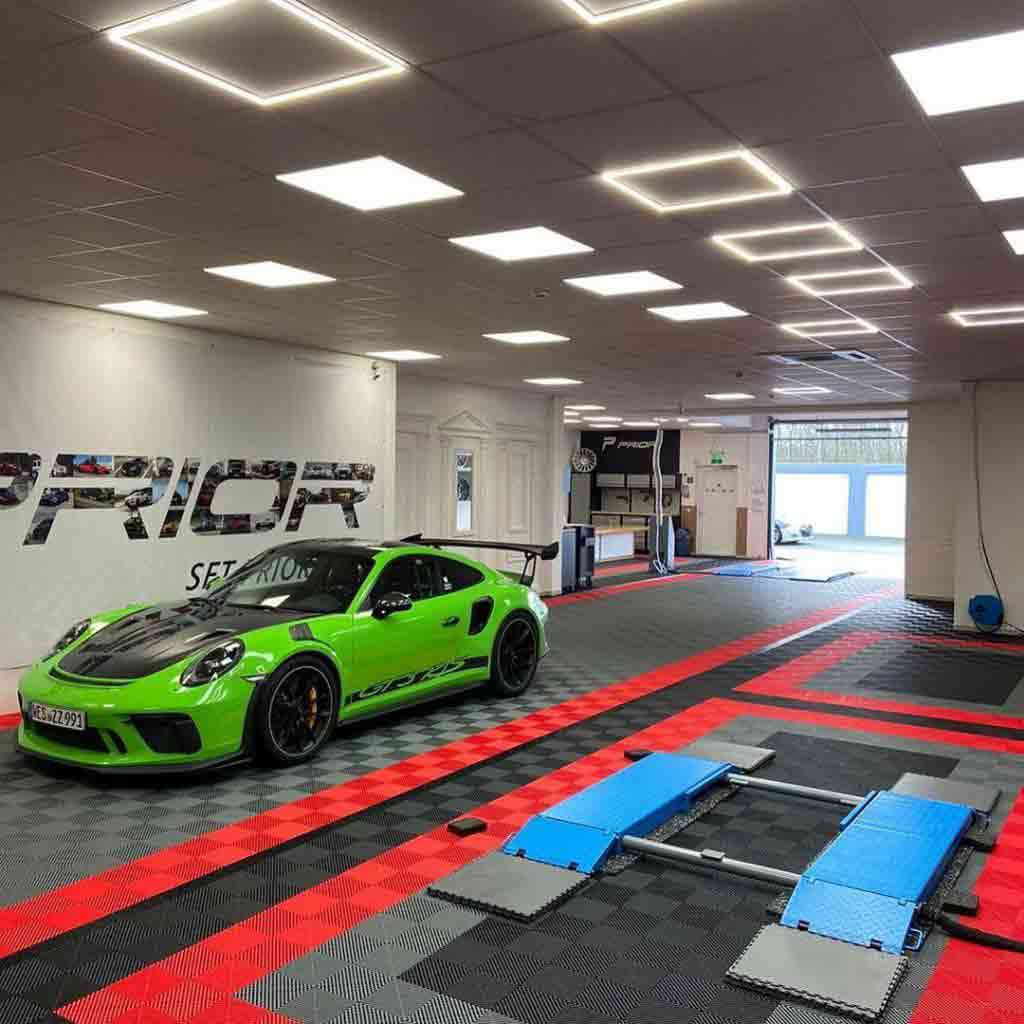

- Some types of tires and wheels can stain tiles over time. This is the result of a chemical reaction that occurs between the antioxidant used in some rubber compounds and the plasticizer used in vinyl . The stain/reaction is brown in colour, so it will not show up on certain colored tiles (dark grey, black, etc.). We recommend considering the use of a two-component polyurethane paint that protects against color changes and stains (such as the Dr. Schutz brand). Tires, hair dye and other harsh chemicals can stain the floor from use . Contact us and you will receive further information from us.

- For better cleaning, a better appearance and a longer lifespan of the floor covering, we recommend the cleaning products from Dr. Protection.

- The tiles of the ECO series (ECOgrey, ECOblack), made from recycled electrical conductors, are not uniform in terms of color and they may contain substances that these electrical conductors contained, eg copper, aluminium, cadmium, lead. Due to the use of ECO input material, ECO tiles may have optical defects on the surface in the form of silvering effect and scattered small particles, which, however, in no way limit the functionality of the tiles. They can also contain the phthalate DEHP (EC 204-211-0; CAS 117-81-7), which belongs to the substances that are subject to the restrictions according to Annex XVII of the REACH regulation. Phthalate esters are not significantly released from our product under normal conditions . The phthalate content in the product can range in concentration from 0 – 5%. Please take this information into account when laying the tiles and use them primarily for industrial and agricultural purposes.

- The subfloor must meet the requirements of the local standard for laying PVC floors.

- The floor coverings are intended for indoor use. When gluing the tiles, they must not be laid in rooms that are not adequately insulated from ground moisture . Avoid moisture (e.g. wet shoes, spilled water) on the substrate being prepared for installation.

- Do not expose flooring to water and long-term relative humidity greater than 75% for periods longer than 24 hours . Operating conditions of the floor covering: air temperature + 10 °C to + 35 °C, relative air humidity (50 ± 10) %.

- Avoid moving objects with sharp edges made of harder materials than PVC. Small stones, grains of sand, sharp furniture, pet claws can scratch the surface. Mount protective elements on objects with sharp edges or corners . Do not move pallets without lifting them. This will avoid scratching the floor.

- Use “W” type wheels for armchairs – soft plastic with a hard core, or PET protective elements for mobile furniture. Provide furniture feet with protective elements made of soft plastic, felt underlays, etc. and regularly check their functionality.

- If the PUR protective layer is damaged by furniture, the contact surfaces of which are not protected by suitable protective elements, no complaint can be accepted for such damage.

- Glowing and glimmering objects leave permanent color and texture changes. Rubber and products made of dark and colored rubber (rubber wheels, pads under equipment, shoe soles, etc.) with prolonged contact with the floor covering can cause permanent color changes of the wear layer , which can be noticed by yellowing, browning and blackening of the floor covering surface at the contact points

- The tiles should not be laid outdoors and the colors are not UV resistant. Direct UV radiation in spectrum C (e.g. germicidal lights, direct sunlight) causes a gradual and permanent color change in the floor covering.

- Compliance with preventive measures, such as the use of sufficiently dimensioned and effective cleaning zones and the use of suitable cleaning and care products for cleaning and maintenance, contribute significantly to the quality and lifespan of the floor covering.

- Hot air welding with a welding cord or cold welding is recommended for a perfect seal and connection of the joints between the tiles. If an adhesive is used, the floor may only be welded and loaded after it has hardened.

- Unfortunately, we are not able to guarantee a 100% color match, this particularly applies to individual product batches. In the case of different batches , this must be taken into account when laying.

- The production process of the Fortelock tiles in Home Decor Design Wood does not allow for an automatic connection of the individual tiles so that the wood decor of the randomly selected tiles matches.

- The tiles are designed to be durable and easy to lay. We have achieved this through the unique puzzle system and production method. This type of manufacture can result in visible marks on the tiles after injection from the center to the edge (applies to Fortelock Industry, Light).

- Although the tiles have a unique moisture wicking system, moisture ingress into the junctions of the squares must be expected and this information must be reflected in the property specifications.

- To ensure that the connections in the corners of the connected tiles hold better, we always recommend rotating the next tile 90 degrees compared to the last one. The logo on the underside of the tile facilitates orientation. This procedure should be followed throughout the installation.

- When the diamond design tiles are stored on pallets, the design can be pushed through into the surrounding tiles. This aspect does not affect the technical characteristics, it is just a visual appearance.

- Although Fortelock PVC tiles are resistant to oils, petrol and other crude oil substances , the tiles should always be cleaned immediately.

- The point load on the floor covering should not exceed 50 MPa.