In today's world, companies are constantly looking for ways

to make their processes more efficient and save costs. One way to achieve this

on the shop floor is to use heavy-duty tiles.

A major advantage of heavy-duty tiles is their quick and

easy installation. Compared to other floor coverings, such as concrete or

coatings, heavy-duty tiles are installed quickly and do not require a long

drying time. As a result, the shop floor can be put back into service more

quickly and there is less downtime.

Another advantage of heavy-duty tiles is their durability

and ease of maintenance. They are easy to clean and maintain, which saves time

and money. In addition, damaged tiles can be easily replaced without having to

replace the entire floor.

Heavy-duty tiles are also a cost-effective solution.

Although the initial price per square foot may be higher than other flooring

options, the investment quickly pays for itself due to its durability and ease

of maintenance. In addition, heavy-duty tiles can usually be installed without

special tools, saving further costs.

Another advantage of heavy-duty tiles is their flexibility.

They can be easily installed over existing floor coverings such as concrete,

wood or tile without having to remove the old covering. This saves time and

money in preparing the subfloor.

Using heavy-duty tiles in the shop floor also offers other

advantages. For example, they are slip-resistant and provide a high level of

grip, which increases work safety and prevents accidents. This is especially

important in areas where oils, greases or other liquids can spill on the floor.

Another advantage of heavy-duty tiles is that they can be

removed quickly and easily when needed. This is especially useful in situations

where a company needs to restructure or expand its factory floor. Heavy-duty

tiles can be removed quickly without damaging the floor, and can be reinstalled

elsewhere if needed.

Heavy-duty tiles are also an environmentally friendly

solution. They are made of recycled material and can be recycled themselves. In

addition, they are durable and do not need to be replaced as often as other

flooring options. This reduces waste and the associated costs. In addition,

some heavy-duty tiles can be made from recycled material, further reducing the environmental

impact.

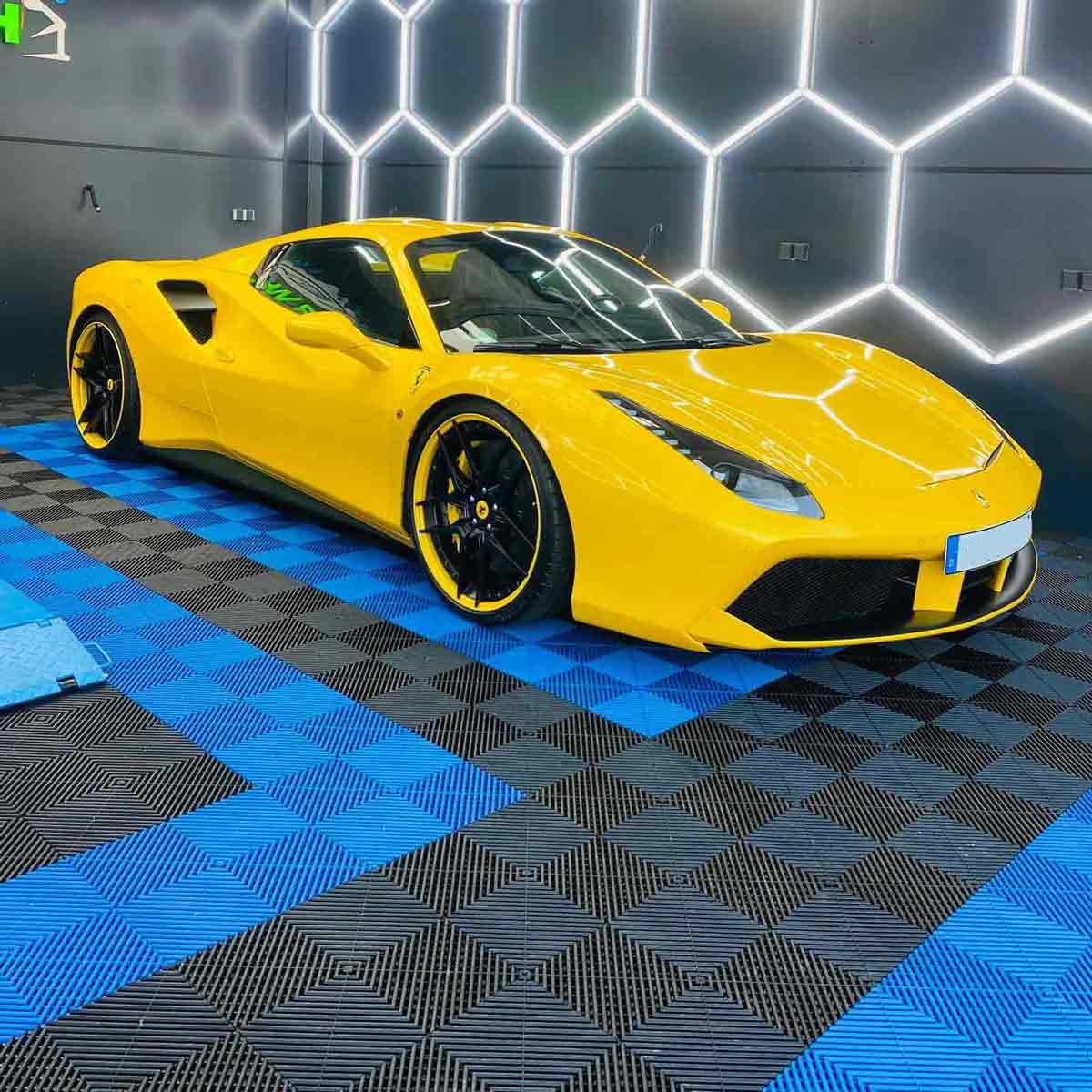

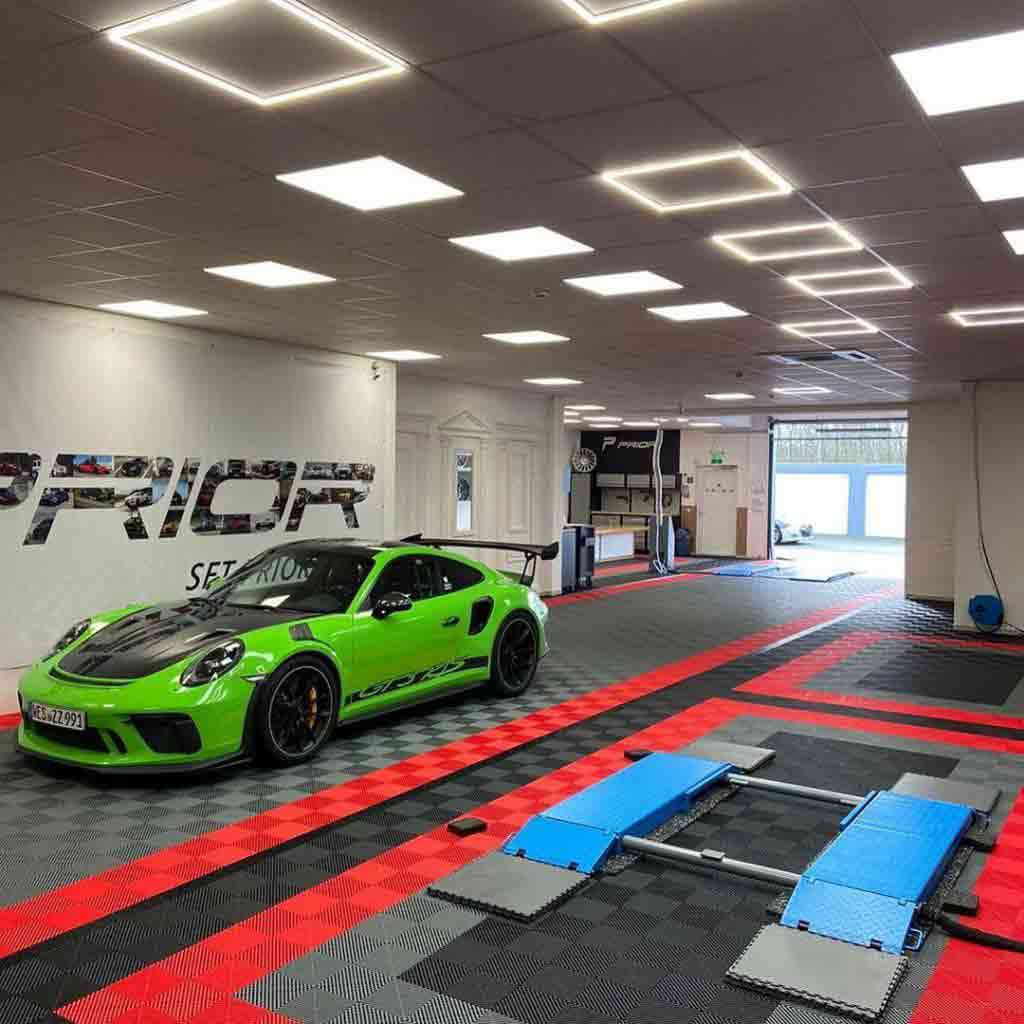

Design of the workshop with robust, heavy-duty tiles.

The design of the workshop is not only for aesthetic

reasons, but can also help to improve safety and efficiency. One way to design

the factory floor while increasing work safety is to use robust, heavy-duty

tiles.

Another benefit of heavy-duty tiles is their flexibility. If

an area of the shop floor needs to be redesigned or expanded, the tiles can be

easily removed and reused elsewhere. This makes them a cost-effective solution

for the long-term design of the shop floor.

The installation of heavy-duty tiles is quick and easy. No

extensive preparation of the substrate is required and the tiles can be

installed without special tools or expertise.