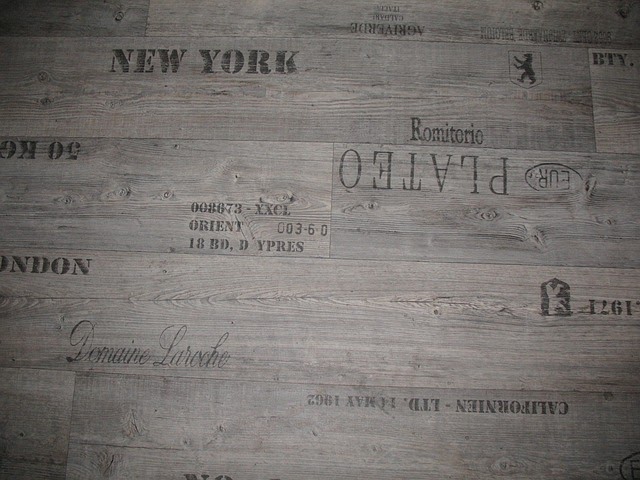

Vinyl - that's what you can expect

Content: 0.96 Quadratmeter (€38.49* / 1 Quadratmeter)

Linoleum, a material that can be used for anything

Linoleum as a floor covering offers many advantages that cannot be denied. Not only is it particularly durable, resilient and extremely pressure-resistant, it is also available in numerous different decors. The material is particularly elastic, which makes it even more popular. Linoleum is also antibacterial, flame retardant, pressure-resistant and easy on the joints. This material is also warm to the feet, which makes it particularly popular. Such a floor also scores with its color stability. Linoleum is also antibacterial. However, the material is sensitive to moisture and therefore rather unsuitable for damp rooms. You should also avoid using alkaline cleaners when cleaning.

Laying linoleum is extremely demanding work. The floor must be fully bonded to the subsurface. In most cases, you need a professional floor installer. Linoleum floors should be waxed regularly. However, if you dig a little deeper into your pocket when purchasing, you can also buy linoleum floors that are already provided with a high-quality protective layer.

PVC (polyvinyl chloride)

Material: PVC is a synthetic material made from petroleum. It also contains plasticizers, stabilizers and other additives to increase its flexibility and durability.

Properties: PVC is waterproof, durable and easy to clean. It is also resistant to many chemicals.

Uses: Because of its water resistance, PVC is often used in wet areas such as bathrooms and kitchens.

Environmental Impact: PVC can be harmful to the environment during manufacturing and disposal, as it contains chlorine and can release harmful dioxins when burned.

Linoleum

Material: linoleum is a natural flooring material made from linseed oil, resins, cork or wood flour, limestone powder and jute fabric.

Properties: linoleum is biodegradable, anti-static and has antibacterial properties. It is also durable and easy to clean.

Uses: linoleum is often used in schools, hospitals and other public buildings.

Environmental Impact: Linoleum is environmentally friendly because it is made from renewable resources and is biodegradable.

Vinyl

Material: vinyl flooring is often made of PVC, so the terms are sometimes used interchangeably. However, there are vinyl floors that do not contain PVC.

Properties: Like PVC, vinyl is waterproof, durable and easy to clean. It is also resistant to stains and abrasion.

Uses: vinyl is often used in living areas, kitchens and bathrooms.

Environmental Impact: The environmental impact of vinyl is similar to that of PVC, as it often contains PVC.

Summary:

PVC and vinyl are synthetic materials, with vinyl often containing PVC. Both are waterproof and durable.

Linoleum is a natural flooring material that is environmentally friendly and biodegradable.

When choosing a flooring material, consider not only aesthetic preferences, but also functionality, durability, and environmental impact.

|

|

PVC (Polyvinylchlorid) |

Linoleum |

Vinyl |

|

Material |

Synthetisch (Erdöl) |

Natürlich (Leinöl, Harze, Kork-/Holzmehl, Kalksteinpulver, Jutegewebe) |

Oft PVC-basiert |

|

Eigenschaften |

Wasserfest, langlebig, leicht zu reinigen, chemikalienbeständig |

Biologisch abbaubar, antistatisch, antibakteriell, langlebig, leicht zu reinigen |

Wasserfest, langlebig, flecken- und abriebfest |

|

Verwendung |

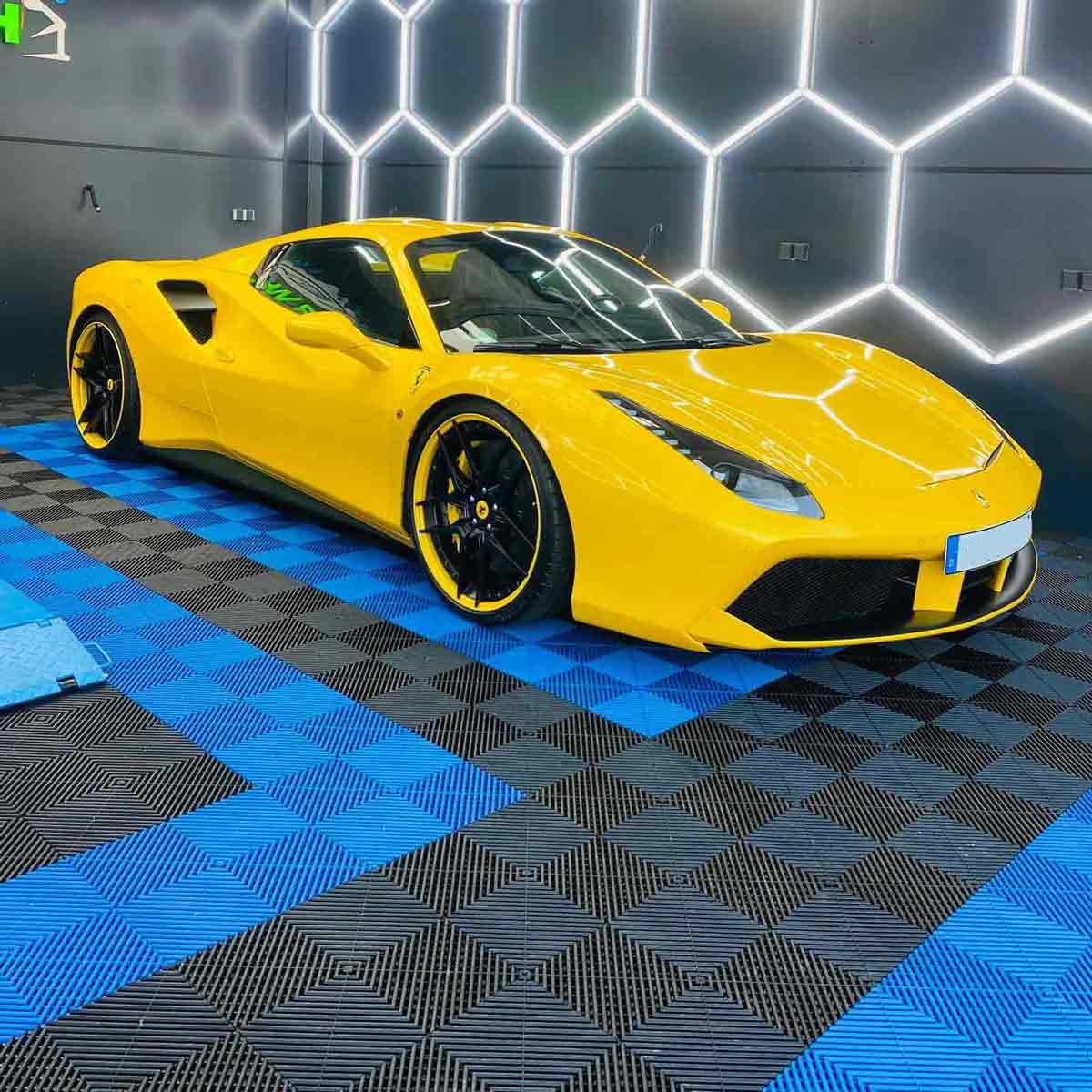

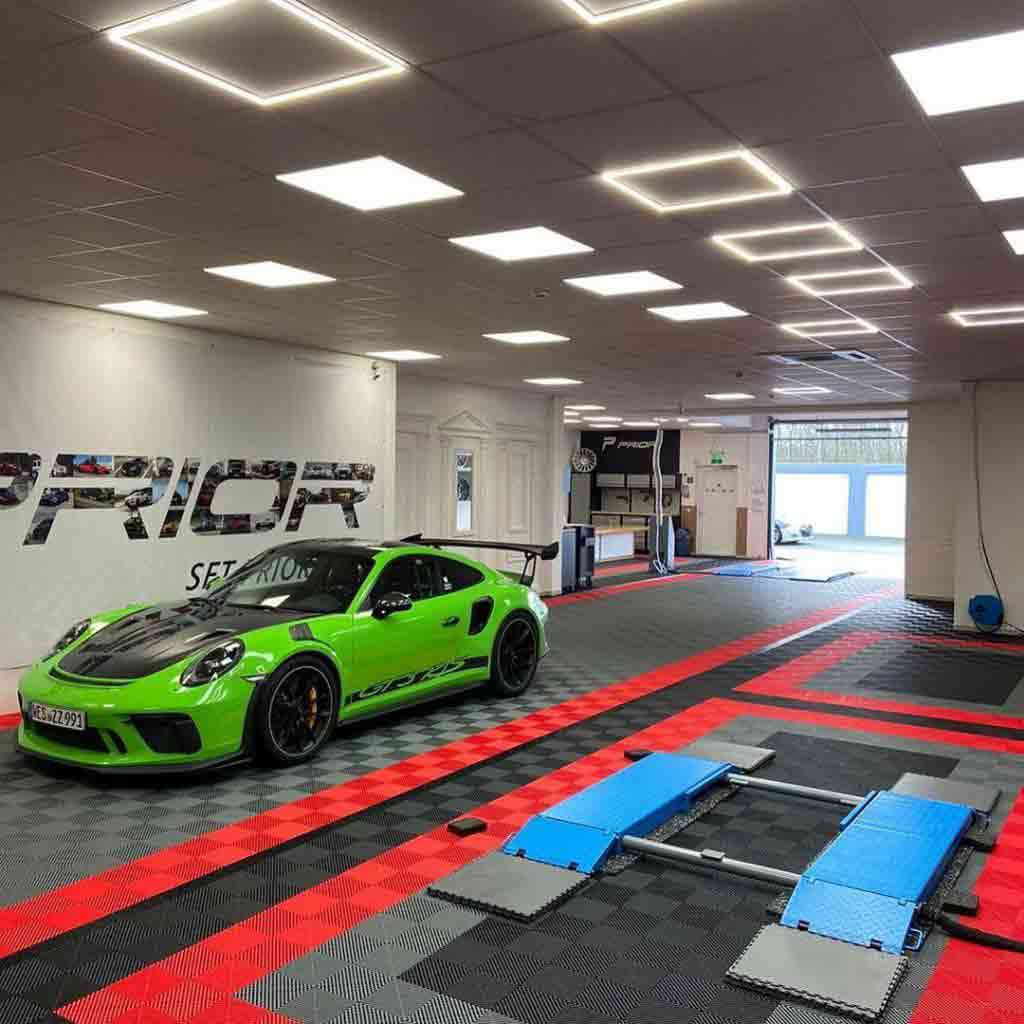

Garagen, Werkstatt |

Schulen, Krankenhäuser, öffentliche Gebäude |

Wohnbereiche, Küchen, Badezimmer |

|

Umweltauswirkungen |

Kann umweltbelastend sein (Chlor, Dioxine bei Verbrennung) |

Umweltfreundlich, biologisch abbaubar |

Ähnlich wie PVC, da oft PVC-basiert |

What is the difference between vinyl and linoleum?

Vinyl and linoleum are both popular flooring materials, but they differ in their composition, manufacturing, properties and environmental impact. Here are the main differences between vinyl and linoleum:

Composition:

- Vinyl: Vinyl floors are made primarily of polyvinyl chloride (PVC) and other synthetic materials. They may also contain plasticizers, stabilizers and other additives.

- Linoleum: Linoleum is a natural flooring made from linseed oil, resins, cork or wood flour, limestone powder and jute fabric.

- Vinyl: Vinyl is made by chemical processes that combine PVC and other materials.

- Linoleum: Linoleum is made by pressing the natural ingredients onto a jute fabric.

- Vinyl: Vinyl is waterproof, durable and easy to clean. It is also resistant to stains and abrasion.

- Linoleum: Linoleum is also durable and easy to clean, but it also has anti-static and anti-bacterial properties. It is not as water resistant as vinyl and can be damaged by constant contact with water.

- Vinyl: Because vinyl is made of PVC, it can be harmful to the environment during manufacturing and disposal. PVC can release harmful dioxins when burned.

- Linoleum: Linoleum is more environmentally friendly than vinyl because it is made from renewable resources and is biodegradable.

- Vinyl: Vinyl floors can last 10 to 20 years or longer, depending on quality and care.

- Linoleum: With proper care, linoleum can last 20 to 40 years or even longer.

- Vinyl: Vinyl is easy to maintain and only requires regular sweeping and mopping.

- Linoleum: Linoleum requires regular sweeping and mopping and occasional polishing to maintain its luster.

Which is better PVC or vinyl flooring?

The terms "PVC" (polyvinyl chloride) and "vinyl flooring" are often used interchangeably, as vinyl flooring is primarily made of PVC. However, there are differences in the quality and composition of vinyl flooring depending on how it is manufactured. When choosing between PVC and vinyl flooring, consider the following factors:

Composition:

PVC: PVC is a plastic that is made from petroleum. It often contains plasticizers, stabilizers and other additives to increase its flexibility and durability.

Vinyl flooring: While vinyl flooring is primarily made of PVC, it may also contain other materials and layers, such as a backing layer, a design layer, and a wear layer.

Design and aesthetics:

PVC: Standard PVC sheets or rolls often have a simpler design and may typically be available in a limited selection of colors and patterns.

Vinyl Flooring: Modern vinyl floors offer a wide range of designs, including those that mimic natural stone, wood and other materials. They may be available in plank, tile or roll form.

Installation:

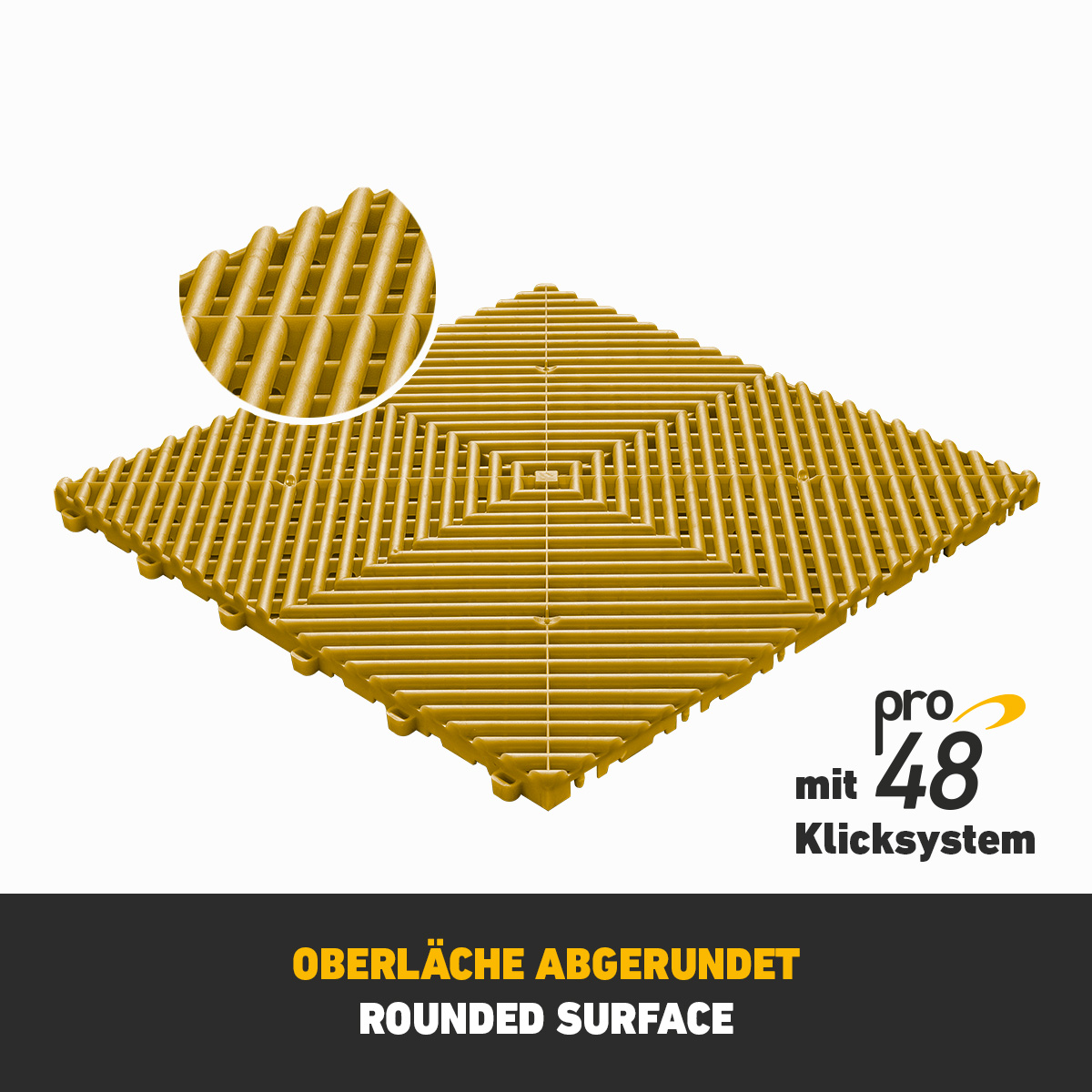

PVC: PVC rolls can be installed in larger areas and often require adhesive for installation.

Vinyl Flooring: There are several installation methods for vinyl flooring, including click systems that allow for a floating installation, as well as self-adhesive vinyl tiles.

Durability and maintenance:

Both materials are water-resistant and easy to clean. However, high-quality vinyl flooring can have a stronger wear layer that makes it more resistant to scratches and wear.

Environmental impact:

Since both PVC and vinyl flooring are made of PVC, they have similar environmental impacts. However, there are more environmentally friendly vinyl flooring options that are made without harmful plasticizers and other chemicals.

Cost:

Costs can vary depending on the quality, brand and design of the vinyl flooring. In general, high-quality vinyl flooring is more expensive than basic PVC rolls.

There is not necessarily a "better" material, as the choice between PVC and vinyl flooring depends on your specific needs, budget and aesthetic preferences. If you're looking for a wider selection of designs and easier installation, vinyl flooring might be the better choice. However, if you're looking for a more cost-effective option for a large area, PVC might be suitable. It's also important to consider the quality and environmental impact of the flooring you choose.

Are vinyl and PVC the same thing?

Vinyl and PVC are often used interchangeably, but technically there is a difference:

PVC (polyvinyl chloride):

- PVC is a plastic polymer and belongs to the vinyl polymer family. It is the third most common synthetic polymer product in the world.

- PVC can come in two main forms: rigid PVC (e.g., for pipes, window frames) and soft PVC (e.g., for cable sheathing), with soft PVC made flexible by adding plasticizers.

- PVC is used in a variety of applications, from construction and plumbing products to medical devices and toys.

Vinyl:

- The term "vinyl" refers to a group of polymers derived from vinyl monomers (such as vinyl chloride). PVC is only one type of vinyl polymer.

- In everyday usage, especially in the context of flooring, "vinyl" is often used as shorthand for "vinyl flooring," which is primarily made of PVC.

- Vinyl can also be used in other contexts, such as vinyl records, which take their name from the use of vinyl polymers in their manufacture.

- While all PVCs are vinyls, not all vinyls are PVCs. However, in many contexts, especially flooring, the terms are often used interchangeably. It is important to know the context in which the term "vinyl" is used to determine whether it specifically means PVC or another type of vinyl polymer.

How to tell if PVC or linoleum?

PVC (vinyl) and linoleum are both common flooring materials, but they have different properties and appearances that allow you to tell them apart. Here are some tips on how to tell if a flooring is PVC or linoleum:

Appearance and texture:

- PVC (vinyl): Vinyl flooring can have a glossier finish and is available in a variety of designs, including those that mimic wood, stone and ceramic. Patterns are often printed on the surface.

- Linoleum: Linoleum often has a deeper, richer color scheme, and the colors and patterns permeate the entire material. This means that the pattern will remain even with wear and tear.

- PVC (vinyl): Vinyl can feel softer and more flexible than linoleum.

- Linoleum: Linoleum often feels firmer and harder than vinyl.

- Linoleum was more popular before the 1960s, so if your home or building was built before that decade, it might be more likely to be linoleum. Vinyl became more popular in the later decades.

- Linoleum: May yellow or discolor over time if exposed to direct sunlight.

- PVC (vinyl): Less prone to discoloration from sunlight.

- PVC (vinyl): Is generally more water resistant than linoleum and is often used in damp areas such as bathrooms.

- Linoleum: Can be damaged by excessive moisture and is not ideal for areas that are constantly wet.

- Linoleum: May have a slight oily odor, especially when new, as it is made from linseed oil.

- PVC (vinyl): May have a chemical odor, especially when new.

- If you can safely remove a small piece of the material and try to burn it (be careful, safety first!), linoleum will not burn as easily as vinyl and will leave a charred edge.